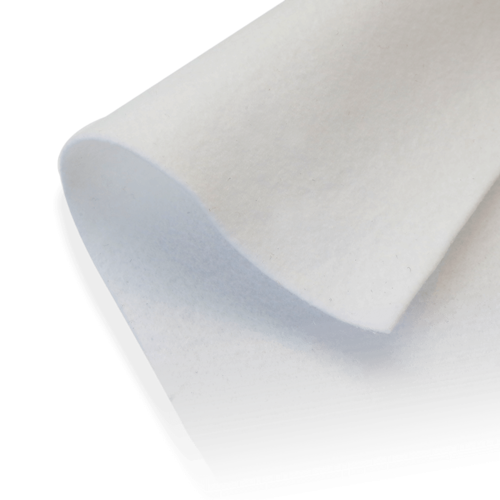

Wicking properties are crucial characteristics of absorbent non-woven fabric, particularly in applications where the even distribution of absorbed liquids is essential. These properties enable the fabric to efficiently transport liquids away from the point of contact, ensuring rapid and uniform absorption. Here's how absorbent non-woven fabric enhances its wicking properties:

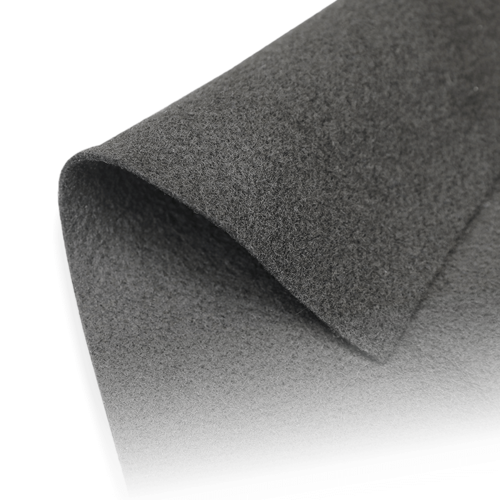

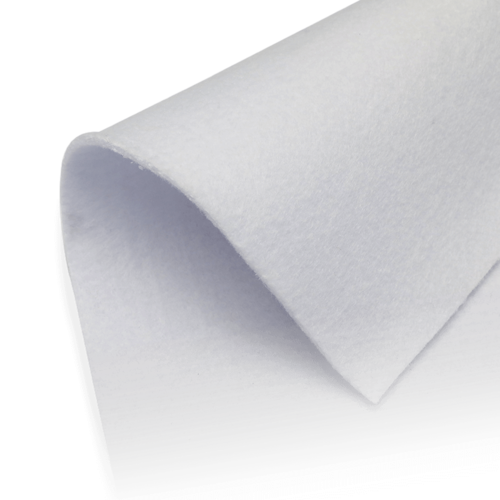

Fiber Orientation: The orientation of fibers within the fabric can be designed to facilitate wicking. Many non-woven fabrics have fibers arranged in a way that promotes capillary action, allowing liquids to be drawn along the fibers.

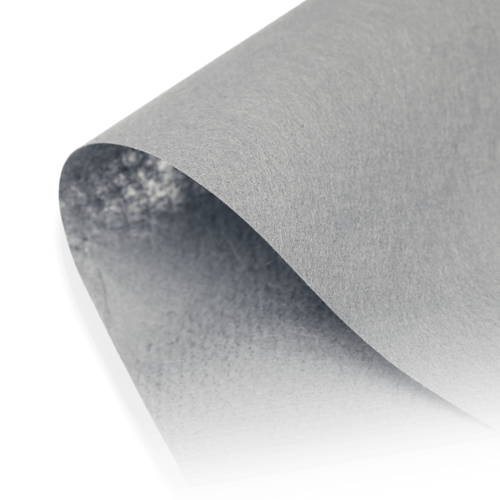

Fiber Type: The choice of fiber material can impact wicking properties. Hydrophilic (water-attracting) fibers, such as cotton, can enhance wicking by readily absorbing and transporting liquids.

Surface Energy: Surface treatments and coatings can be applied to non-woven fabrics to increase their surface energy and improve wettability. This encourages liquids to spread and wick more efficiently across the fabric.

Porous Structure: The porous nature of non-woven fabrics provides pathways for liquids to move through. The fabric's interconnected pores facilitate the flow of liquids from one area to another.

Capillary Action: Non-woven fabrics are often designed to promote capillary action, where liquid is drawn into the fabric through small openings or channels between fibers. This action helps liquids move through the fabric quickly.

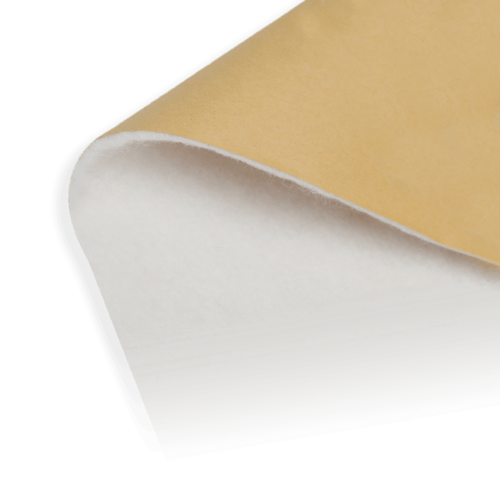

Multilayer Design: In products like diapers or wound dressings, multiple layers of absorbent non-woven fabric may be used in a sandwich-like structure. The top layer is designed for rapid wicking, while lower layers are optimized for liquid retention.

Absorbent Additives: Some non-woven fabrics incorporate superabsorbent polymers (SAPs) that can rapidly absorb liquids and aid in their efficient distribution within the fabric.

Hydrophilic Treatments: Non-woven fabrics can be treated with hydrophilic chemicals or finishes that enhance their affinity for water and promote rapid wicking.

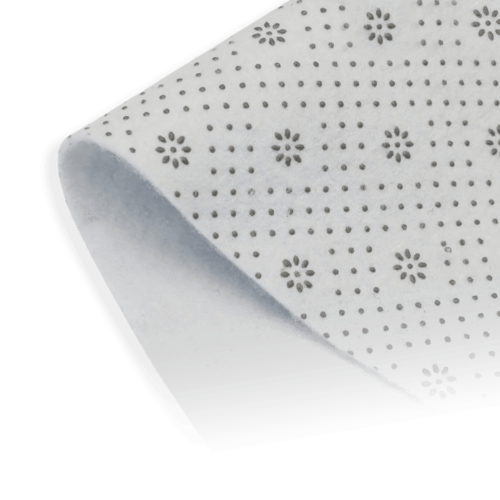

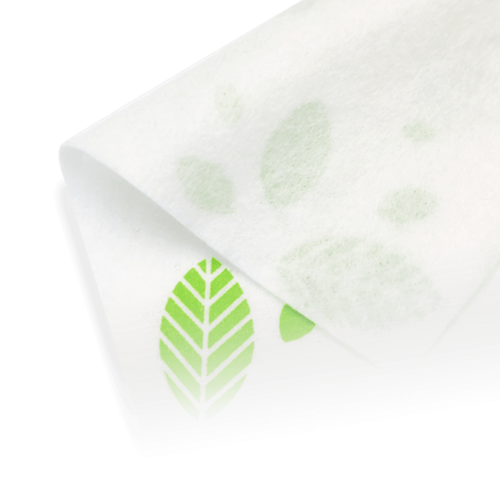

Patterned Surface: Patterned or embossed surfaces on non-woven fabrics can create channels that guide liquids, aiding wicking and distribution.

Application-Specific Engineering: Manufacturers tailor the wicking properties of absorbent non-woven fabrics to meet the specific requirements of different applications. For example, medical dressings may need to wick wound exudate away from the skin surface, while automotive spill cleanup materials must transport and contain spilled fluids.

Efficient wicking properties ensure that absorbent non-woven fabrics quickly transport liquids away from the source, minimizing the risk of saturation and enhancing overall performance in applications such as diapers, feminine hygiene products, medical pads, and spill control materials. The combination of wicking with other properties like absorbency and liquid retention makes these fabrics versatile and effective in managing moisture in various contexts.

English

English Español

Español Deutsch

Deutsch عربى

عربى