In the realm of public transportation, safety is not a luxury—it’s an imperative. As millions of people navigate cities and regions daily, ensuring their protection is a responsibility that extends to every detail, including the materials used in vehicle interiors. Among these materials, flame-retardant non-woven fabrics have emerged as unsung heroes, playing a pivotal role in mitigating fire risks.

The Composition and Science Behind Non-Woven Fabrics

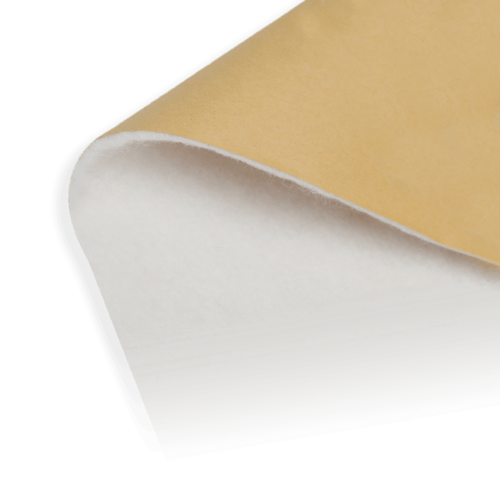

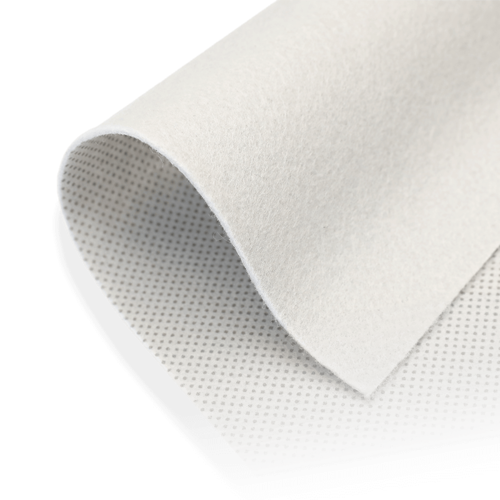

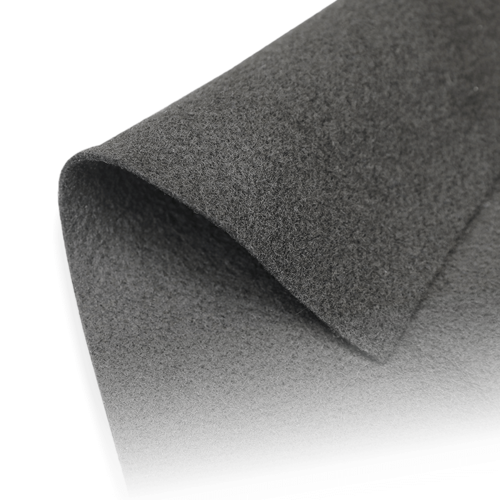

Non-woven fabrics differ fundamentally from their woven counterparts. Constructed through bonding fibers together using chemical, mechanical, or thermal processes, these fabrics offer exceptional versatility. When engineered with flame-retardant properties, they become formidable barriers against fire hazards.

Flame-retardant additives, infused during production, alter the fabric’s combustion behavior. These additives either form a protective char layer when exposed to flames or release non-flammable gases that dilute oxygen in the immediate vicinity. The result? Delayed ignition, reduced flame spread, and minimized smoke production—critical factors in enhancing passenger safety.

Application in Public Transportation

From bus seat upholstery to train cabin wall linings, flame-retardant non-woven fabrics are omnipresent. Their lightweight nature and durability make them ideal for use in high-traffic environments, where wear and tear are constant concerns. These fabrics serve as a first line of defense in fire scenarios, buying crucial time for evacuation and emergency response.

In aviation, where fire safety standards are exceptionally stringent, non-woven fabrics are indispensable. They not only meet but often exceed regulatory requirements, offering unparalleled protection without compromising on aesthetic appeal or passenger comfort.

Regulatory Compliance and Standards

The adoption of flame-retardant non-woven fabric is driven by rigorous fire safety standards. Globally recognized benchmarks such as the FMVSS 302 (Federal Motor Vehicle Safety Standard) and the EN 45545-2 (European Standard for Railway Applications) mandate stringent fire resistance levels. Non-woven fabrics engineered for compliance with these standards ensure public transportation systems adhere to the highest safety protocols.

Advantages Beyond Fire Safety

The benefits of flame-retardant non-woven fabrics extend beyond their fire-resistant properties. These materials are cost-effective, recyclable, and adaptable to various design specifications. Their acoustic insulation capabilities enhance passenger comfort, while their low-maintenance requirements reduce operational costs. Additionally, advancements in eco-friendly flame retardants underscore their alignment with sustainability goals.

The Future of Fire Safety in Transit

As transportation systems evolve, the demand for innovative safety solutions grows. Flame-retardant non-woven fabrics represent a fusion of cutting-edge science and practical application. Emerging technologies, such as nanotechnology and bio-based retardants, promise to elevate their performance further, ensuring they remain integral to fire safety strategies.

In public transportation, where safety cannot be compromised, flame-retardant non-woven fabrics stand as a testament to the power of innovation. By mitigating fire risks, these materials safeguard lives and inspire confidence among passengers. As industries continue to prioritize safety and sustainability, these fabrics will undoubtedly play a central role in shaping the future of secure and resilient transit systems.

English

English Español

Español Deutsch

Deutsch عربى

عربى