The automotive industry is continually evolving, and as consumer expectations rise, so does the demand for innovative solutions that elevate vehicle performance, comfort, and longevity. One such solution gaining significant attention is automotive interior non-woven fabric. Though often understated, this material plays a pivotal role in enhancing the durability and overall lifespan of car interiors, making it an indispensable component for modern vehicles.

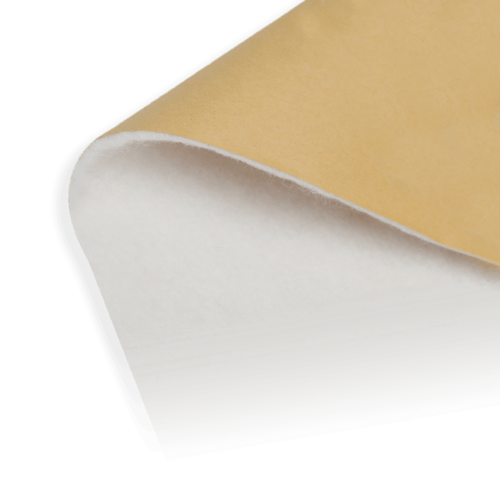

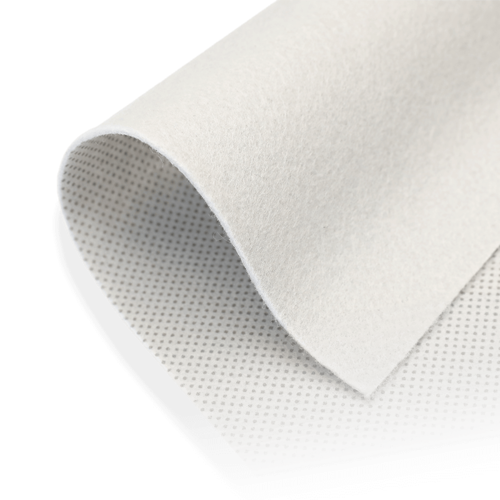

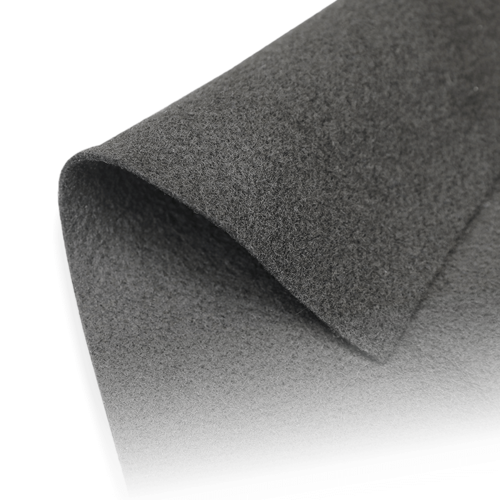

Non-woven fabric is a versatile, engineered textile produced by bonding fibers through heat, pressure, or adhesive methods. Unlike traditional woven fabrics, it does not require the interlacing of threads, which makes it lighter, more flexible, and highly durable. Automotive manufacturers have leveraged these unique qualities to craft materials that can withstand the rigors of daily use while maintaining their functionality and appearance over time.

Durability in the Face of Wear and Tear

Car interiors are subjected to continuous stress—from the constant friction of passengers entering and exiting to the pressures of climate conditions. In such an environment, fabrics that show signs of wear can quickly detract from the vehicle's aesthetic and, more importantly, its functionality. Non-woven fabrics, however, exhibit remarkable resistance to abrasion. Their durable structure ensures they can endure prolonged exposure to friction without suffering damage, ensuring that the vehicle's upholstery retains its appearance longer than traditional materials.

Moreover, non-woven fabrics are often engineered to be resistant to stretching and deformation. This characteristic ensures that the material maintains its original shape, even after repeated use, effectively preventing unsightly sagging or wear marks that are common in less durable fabrics.

Resilience Against Environmental Stressors

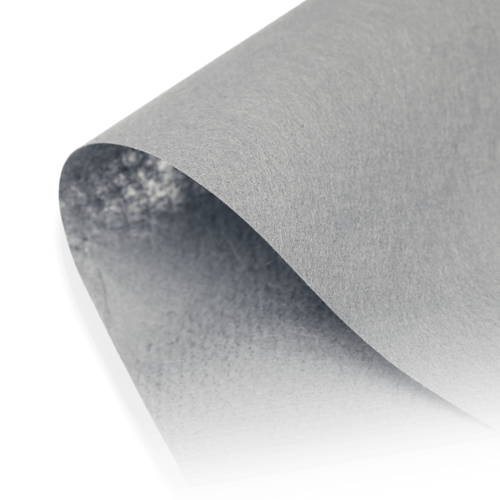

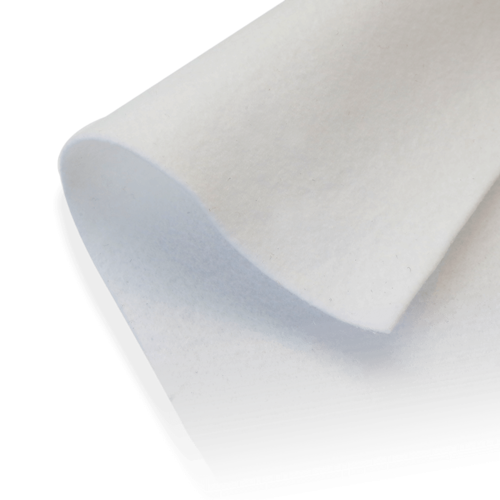

Automotive interiors are routinely exposed to environmental stressors—extreme temperatures, humidity, UV rays, and even the occasional spillage. Non-woven fabrics are inherently resistant to moisture, which significantly reduces the risk of mold and mildew formation. Their ability to resist moisture absorption keeps interior components dry, which not only preserves the integrity of the fabric itself but also prevents potential damage to underlying layers or components, such as foam or padding, that could deteriorate over time.

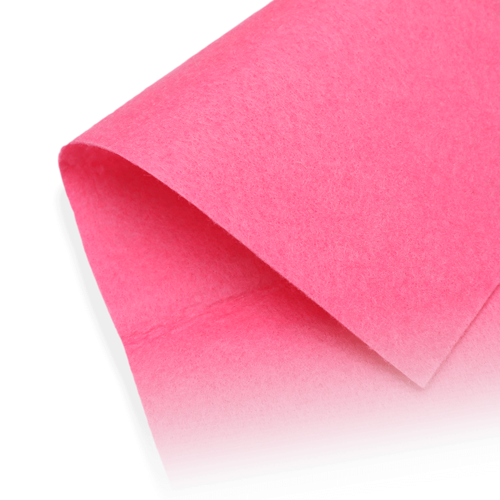

Furthermore, non-woven materials are often treated with UV inhibitors, protecting them from the damaging effects of prolonged sun exposure. This added layer of defense helps to maintain the vibrant color and texture of car interiors, preventing premature fading or degradation. The result is a more durable, long-lasting surface that can withstand years of use without significant visual or structural compromise.

Enhanced Comfort and Insulation

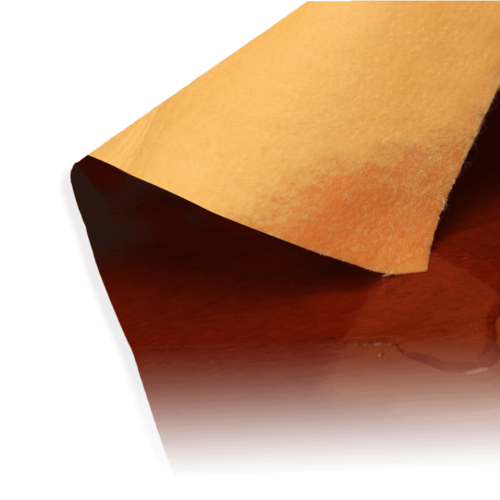

In addition to their durability, non-woven fabrics contribute to the overall comfort and user experience of a vehicle. Due to their superior insulating properties, they help regulate interior temperature, providing a more comfortable ride regardless of external weather conditions. This insulating effect also helps minimize noise, contributing to a quieter cabin environment—further improving the overall driving experience.

Non-woven materials also support enhanced cushioning and padding. Whether used in seat covers, headliners, or floor mats, they provide a softer, more comfortable surface for passengers. The material’s ability to absorb impacts and resist compression ensures that these comfort features last longer, maintaining their structural integrity for the vehicle’s lifespan.

Sustainability and Cost-Effectiveness

As the automotive industry increasingly shifts toward sustainability, non-woven fabrics offer an environmentally friendly solution. Many non-woven materials are now produced using recycled fibers, reducing the environmental impact of their production. Additionally, the reduced weight of non-woven fabrics contributes to better fuel efficiency, as lighter materials place less strain on the vehicle’s overall performance.

From a cost perspective, non-woven fabrics offer an attractive alternative to traditional materials. Their lower production cost and ease of manufacture make them a more cost-effective option for automakers, allowing them to achieve high performance without significantly driving up vehicle prices. For consumers, this translates into a more affordable option without compromising on quality or durability.

Incorporating automotive interior non-woven fabric into vehicle design significantly elevates the durability and longevity of car interiors. By offering resistance to wear, environmental stressors, and the daily rigors of use, non-woven fabrics provide an unparalleled combination of strength, comfort, and sustainability. As the automotive industry continues to prioritize both performance and aesthetics, this material will remain a cornerstone of interior design, ensuring vehicles maintain their beauty and functionality over time.

English

English Español

Español Deutsch

Deutsch عربى

عربى