In the realm of hygiene products, the demand for superior performance, comfort, and safety continues to grow. Diapers and sanitary pads, two of the most widely used products in this category, rely heavily on advanced materials to meet consumer expectations. Among these materials, laminated non-woven fabric stands out as a transformative innovation, offering a blend of functionality and comfort.

Unraveling Laminated Non-Woven Fabric

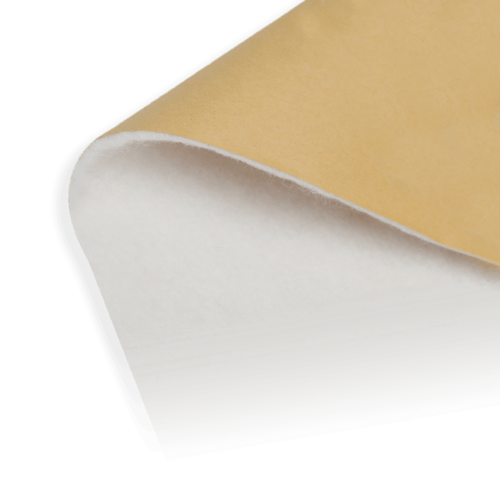

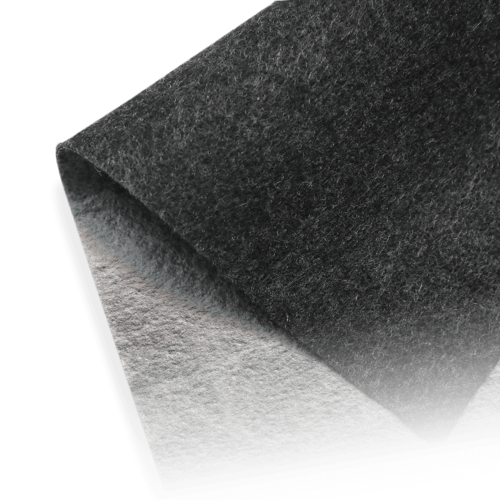

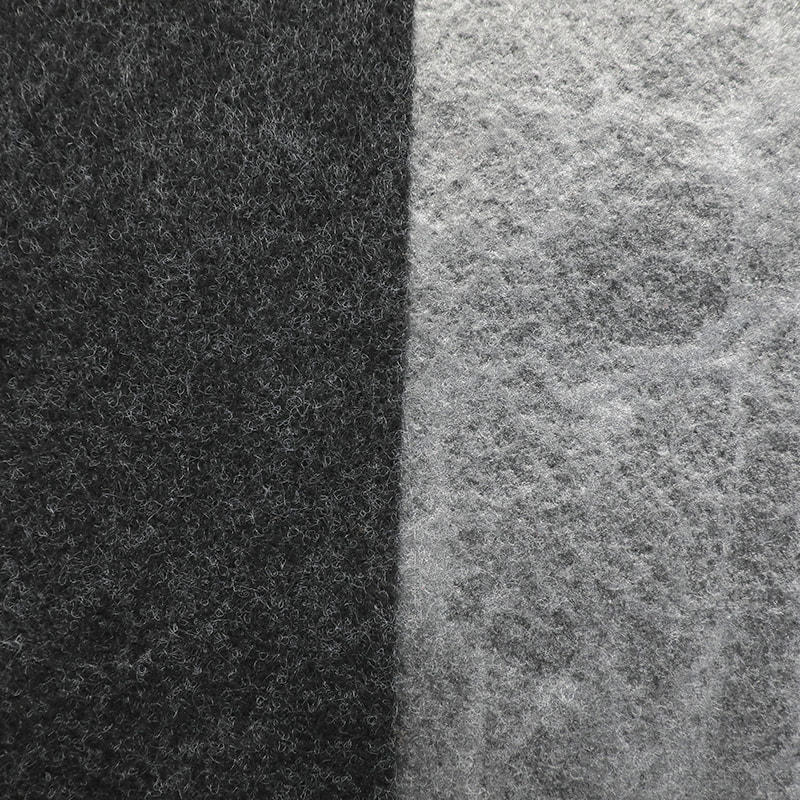

Laminated non-woven fabric is a multi-layered material composed of non-woven substrates bonded together, often with an additional film layer for enhanced properties. This process integrates the flexibility and breathability of non-woven fibers with the protective qualities of laminates, resulting in a fabric that is soft, durable, and impermeable to moisture.

This combination is not arbitrary; it is carefully engineered to address specific requirements in hygiene products. From providing an effective barrier to preventing leakage, laminated non-woven fabric is the unsung hero in ensuring comfort and protection.

Enhanced Absorbency and Moisture Control

One of the most critical attributes of laminated non-woven fabric is its ability to manage moisture effectively. In diapers and sanitary pads, controlling fluid absorption and retention is paramount. The laminated layer adds an extra line of defense, ensuring that liquids are quickly drawn away from the surface and securely locked within the core.

This rapid moisture-wicking feature not only minimizes the risk of leakage but also keeps the skin dry, reducing the likelihood of irritation or rashes. The result is a more comfortable experience for the wearer, particularly for prolonged use.

Improved Strength and Durability

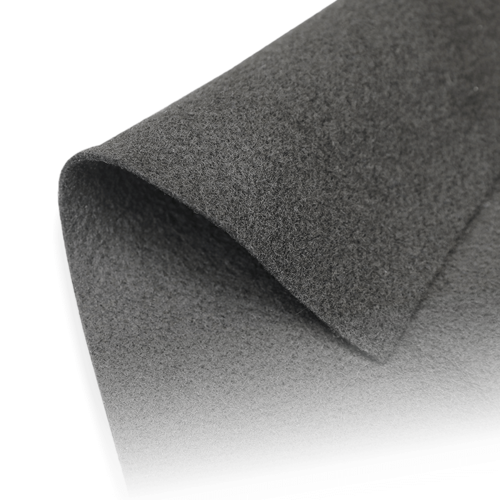

Hygiene products are subjected to constant movement and strain. Laminated non-woven fabric provides the necessary structural integrity to withstand these demands. Unlike traditional materials, it resists tearing, even under pressure, ensuring the product remains intact during use.

Moreover, its lightweight nature ensures that durability does not come at the expense of comfort. The fabric feels soft against the skin, making it suitable for sensitive users, including infants and individuals with delicate skin.

Breathability Meets Protection

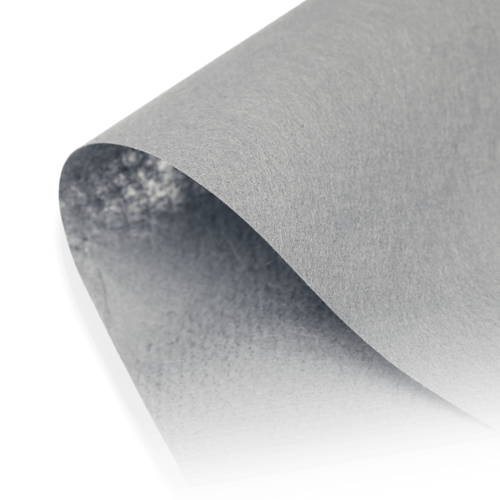

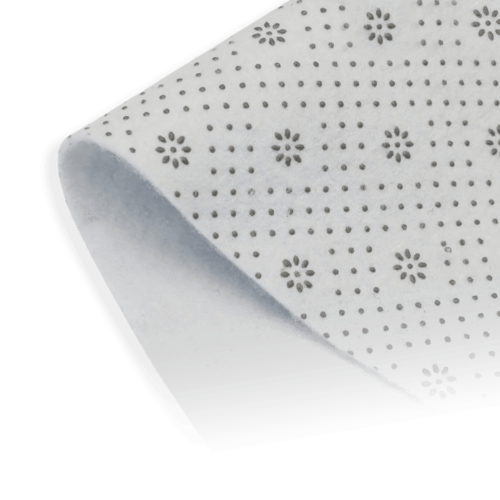

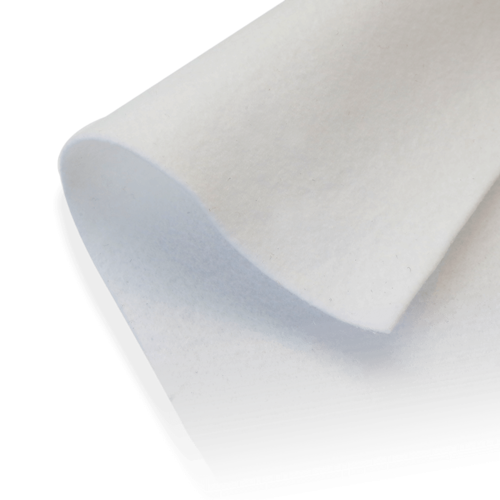

While creating a moisture barrier is essential, breathability cannot be overlooked. Laminated non-woven fabric strikes the perfect balance between impermeability and air circulation. The inclusion of micro-porous laminates allows air to pass through while blocking liquids, maintaining a fresh and hygienic environment.

This feature is particularly significant in hygiene products, where prolonged use can lead to heat buildup. By promoting ventilation, the fabric enhances overall comfort and reduces the risk of bacterial growth, thereby improving hygiene.

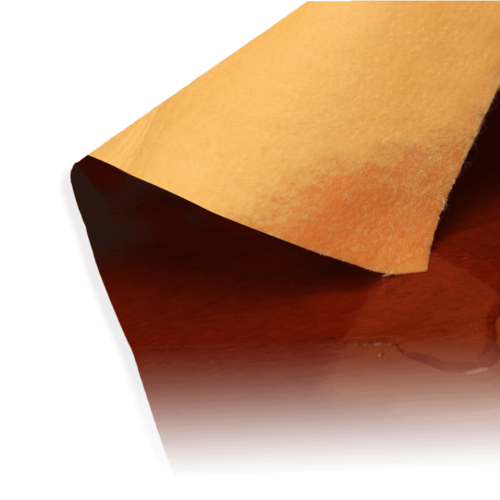

Customization for Enhanced Performance

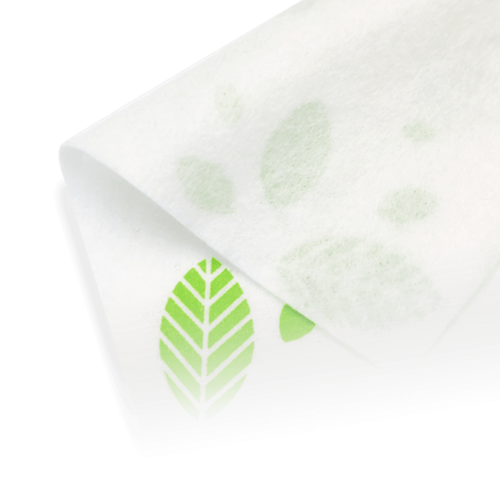

Manufacturers of hygiene products benefit from the versatility of laminated non-woven fabric. It can be customized to meet specific product requirements, such as varying thickness, elasticity, or surface texture. These adjustments allow the material to cater to different demographics, from ultra-thin sanitary pads for discretion to extra-absorbent diapers for overnight use.

Additionally, advancements in printing technology enable branding and aesthetic customization without compromising functionality. This flexibility makes laminated non-woven fabric a preferred choice for innovative product designs.

A Sustainable Edge

Modern consumers are increasingly aware of environmental concerns, and laminated non-woven fabrics can align with these values. Many manufacturers now utilize eco-friendly materials and production processes, reducing the carbon footprint of hygiene products. Some laminates are also designed to be biodegradable, ensuring a reduced environmental impact post-use.

Laminated non-woven fabric has redefined the standards of hygiene products like diapers and sanitary pads. By combining absorbency, durability, breathability, and customization, it provides unmatched performance and user satisfaction. As consumer expectations evolve, the role of this material will only grow, driving innovations that prioritize both comfort and sustainability.

English

English Español

Español Deutsch

Deutsch عربى

عربى