When it comes to non-woven fabrics, needle-punched felt non-woven fabric has carved out a niche of its own, thanks to its versatility and durability. But have you ever wondered how the density of this fabric affects its overall strength and longevity?

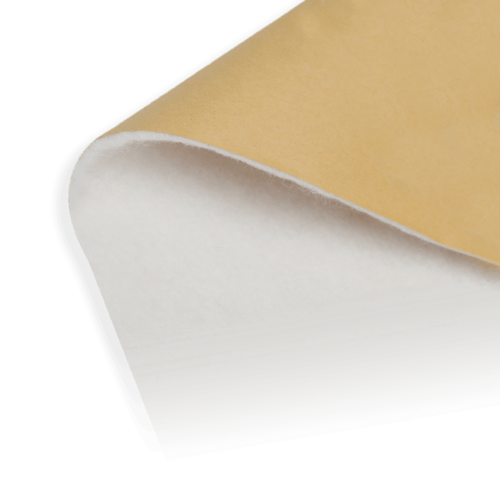

Needle-punched felt non-woven fabric is created by entangling fibers through a process involving barbed needles. This method offers a robust fabric that can be used in a myriad of applications—from automotive interiors to home décor. But what exactly do we mean by density? In essence, fabric density refers to the mass of fibers packed into a given area. A higher density means more fibers per square inch, while a lower density indicates a more sparse arrangement.

So, why does this matter? Well, a higher density typically leads to a stronger and more durable fabric. This is because the increased number of fibers contributes to the fabric's ability to withstand stress, resist tearing, and endure wear and tear over time. However, it’s crucial to strike a balance, as too much density can lead to stiffness, affecting flexibility and comfort.

Strength: More Density, More Power!

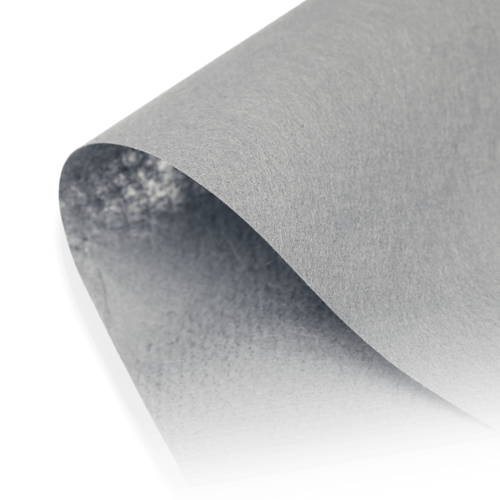

One of the primary benefits of higher density needle-punched felt non-woven fabric is its remarkable strength. According to a study published in the Journal of Textile Science, fabrics with a density of 300 g/m² exhibited a tensile strength increase of up to 40% compared to those with lower densities. This means that if you're looking for a fabric that can withstand heavy use, opting for a denser option is your best bet.

In practical terms, consider the use of needle-punched felt non-woven fabric in the automotive industry. Car interiors face constant wear from passengers, sun exposure, and temperature changes. A dense felt can resist the abrasive impacts of everyday use while maintaining its integrity, leading to longer-lasting products that don’t need frequent replacements.

Durability: The Long Game

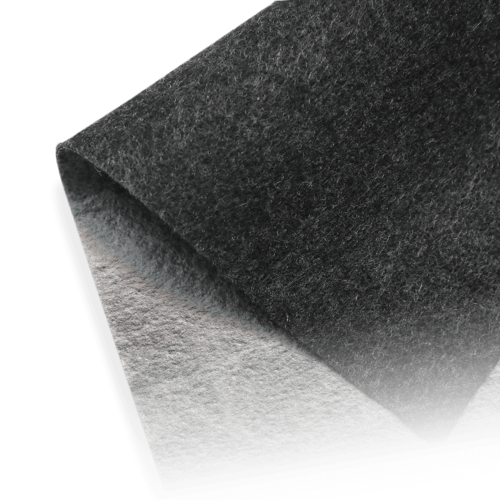

Durability is another critical aspect where fabric density plays a vital role. Higher density needle-punched felt non-woven fabric exhibits better resistance to environmental factors, such as moisture and UV rays. This is particularly important for applications like roofing or outdoor furniture, where exposure to the elements is inevitable.

According to the American Society for Testing and Materials (ASTM), needle-punched felt non-woven fabric with a density of 400 g/m² showed a marked improvement in resistance to water absorption, which contributes to its longevity. This means that not only does denser felt last longer, but it also performs better under challenging conditions, making it a wise investment for both manufacturers and consumers.

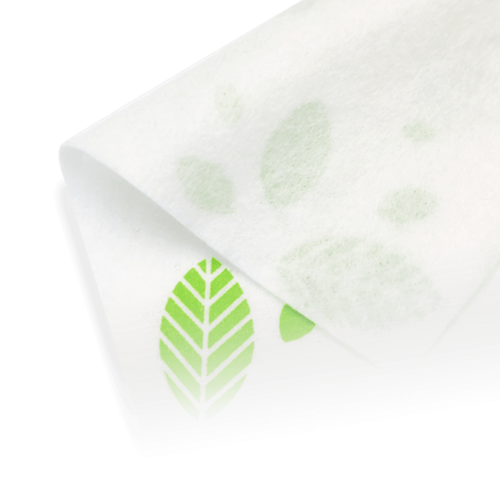

The density of needle-punched felt non-woven fabric is a key factor influencing its strength and durability. Higher density fabrics provide enhanced strength, making them suitable for demanding applications, while also offering greater durability against environmental factors. However, it’s essential to consider the specific requirements of your project, as too much density can lead to rigidity.

English

English Español

Español Deutsch

Deutsch عربى

عربى