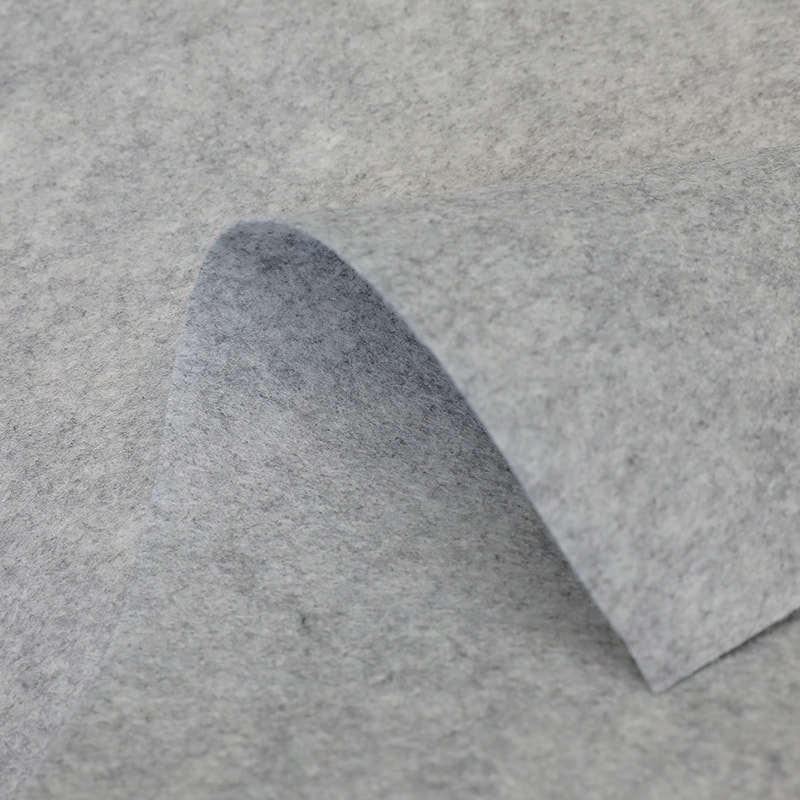

Flame-retardant non-woven fabric has become increasingly popular in various applications, especially in the fields of personal protective equipment, home textiles, and industrial materials. One of the key attributes of these fabrics is their flame-retardant performance, which is crucial for ensuring safety in environments where fire hazards are present. However, a pressing question arises: how does the flame-retardant performance of flame-retardant non-woven fabric change over time or after washing?

The Basics of Flame Retardancy in flame-retardant non-woven fabric

Flame-retardant non-woven fabrics are typically treated with chemical agents that inhibit ignition and slow down the spread of flames. These agents can be either incorporated during the manufacturing process or applied as a finishing treatment. The effectiveness of these treatments is often measured by standards such as ASTM E84 or NFPA 701, which assess the material's resistance to burning.

Over time, the flame-retardant properties of these fabrics can degrade due to various factors such as exposure to heat, light, and environmental conditions. Additionally, the physical and chemical integrity of the fabric itself can be compromised through repeated use and washing.

The Impact of Washing on Flame Retardancy

One of the most significant variables affecting the flame-retardant performance of flame-retardant non-woven fabric is washing. Many consumers may not realize that the effectiveness of flame retardants can diminish after multiple washes. A study published in the Journal of Fire Sciences found that certain flame-retardant treatments could lose up to 50% of their effectiveness after just five wash cycles. This is particularly concerning for garments and textiles that require regular cleaning.

Washing not only removes dirt and grime but can also wash away the chemical agents that impart flame-retardant properties. Additionally, the mechanical action during washing can physically damage the fabric, leading to micro-tears that further compromise its protective qualities. Therefore, it's essential for manufacturers to provide clear care instructions and choose durable flame-retardant treatments that can withstand laundering.

Longevity and Environmental Factors

Flame-retardant performance does not only diminish through washing; it can also be affected by environmental factors such as UV exposure and humidity. Prolonged exposure to sunlight can break down the chemical bonds of flame-retardant agents, leading to a reduction in effectiveness. Similarly, high humidity levels can cause the fabric to absorb moisture, which may interfere with the flame-retardant chemicals.

A recent study showed that flame-retardant non-woven fabric exposed to UV light for extended periods exhibited a 30% reduction in flame-retardant performance compared to those kept in controlled conditions. This highlights the importance of considering the environment in which the fabric will be used and stored.

The flame-retardant performance of flame-retardant non-woven fabric is influenced by several factors, including washing, environmental exposure, and the durability of the chemical treatments used. Consumers should be aware that regular laundering can significantly reduce the effectiveness of these protective materials, and they should follow care instructions diligently. Manufacturers, on the other hand, must prioritize the development of robust flame-retardant treatments that can withstand the rigors of daily use and environmental challenges. As safety remains a top priority, understanding the dynamics of flame-retardant performance will help ensure that flame-retardant non-woven fabric continue to provide the protection needed in various applications.

English

English Español

Español Deutsch

Deutsch عربى

عربى