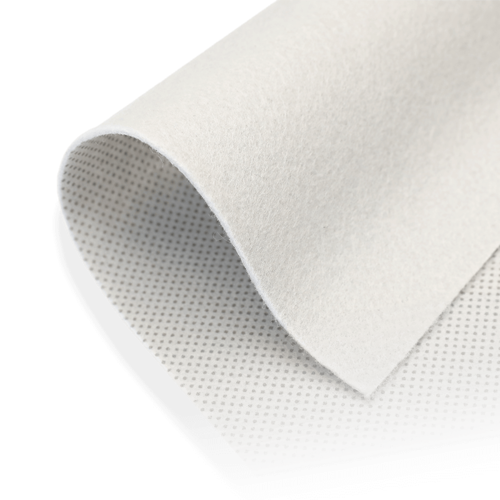

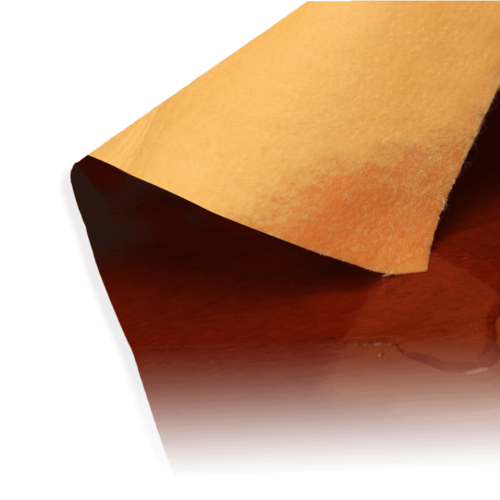

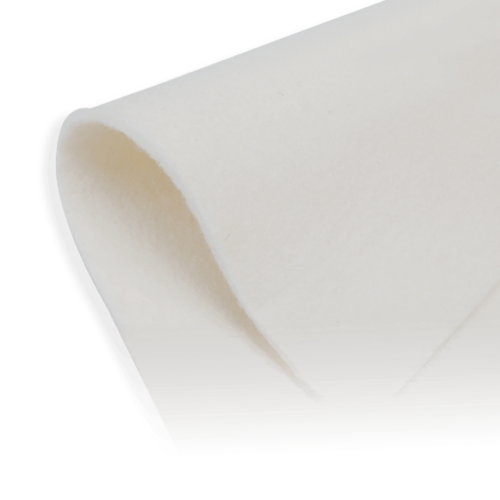

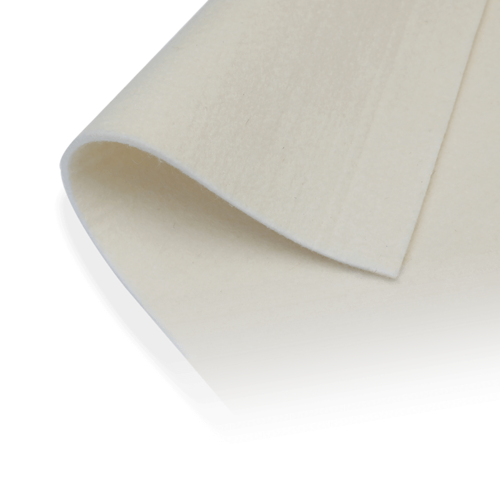

Polypropylene non-woven fabric can be recycled through various processes. Here are some common methods used for recycling polypropylene non-woven fabric:

Mechanical Recycling: Mechanical recycling involves the use of physical processes to break down the non-woven fabric into smaller pieces or fibers. These smaller pieces can then be melted and processed into new polypropylene products. The process typically includes shredding or grinding the fabric into flakes, which are then melted and extruded to form new fibers or molded into different shapes.

Melt Blending: In this method, the polypropylene non-woven fabric is melted and blended with other materials to create a composite material. The blend can include other polymers, additives, or recycled materials. This mixture is then processed to create new products such as plastic lumber, composite decking, or other injection-molded items.

Thermal Conversion: Thermal conversion involves using high temperatures to convert the polypropylene non-woven fabric into energy or other useful products. This method includes processes like pyrolysis, where the fabric is heated in the absence of oxygen to break it down into its constituent components, such as liquid fuels, gases, and char.

Chemical Recycling: Chemical recycling utilizes chemical processes to break down the polypropylene non-woven fabric into its original monomers, which can then be used to produce new polypropylene. This method involves processes like depolymerization, where the fabric is treated with solvents or chemicals to break the polymer chains and separate the monomers.

It's worth noting that the availability and applicability of these recycling methods may vary depending on local infrastructure and facilities. Some recycling facilities may specialize in specific techniques, while others may combine multiple methods to achieve efficient recycling of polypropylene non-woven fabric.

English

English Español

Español Deutsch

Deutsch عربى

عربى