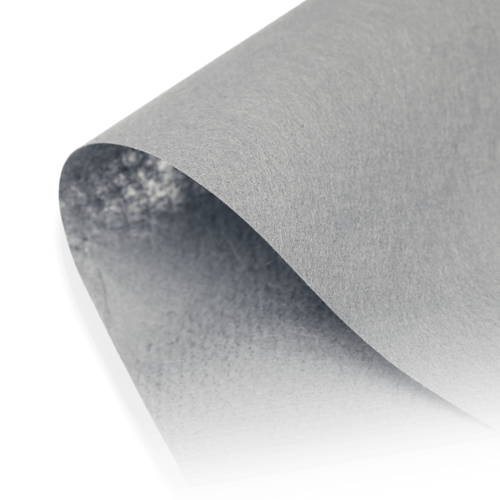

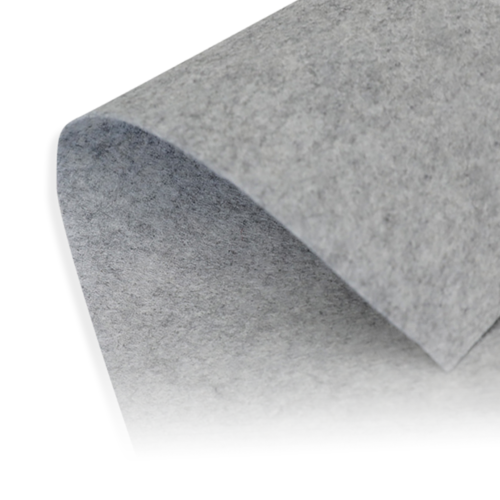

Needle-punched felt non-woven fabric has emerged as a versatile and essential material in various industries, thanks to its unique properties and manufacturing process. This innovative fabric is created by entangling fibers through a specialized needle-punching technique, resulting in a strong, durable, and flexible material with a wide range of applications.

The manufacturing process of needle-punched felt non-woven fabric involves feeding a web of loose fibers through a needle-punching machine. The machine is equipped with thousands of barbed needles that repeatedly penetrate the fiber web, entangling and intertwining the fibers to create a cohesive fabric structure. This process eliminates the need for weaving or knitting, making it a cost-effective and efficient method of fabric production.

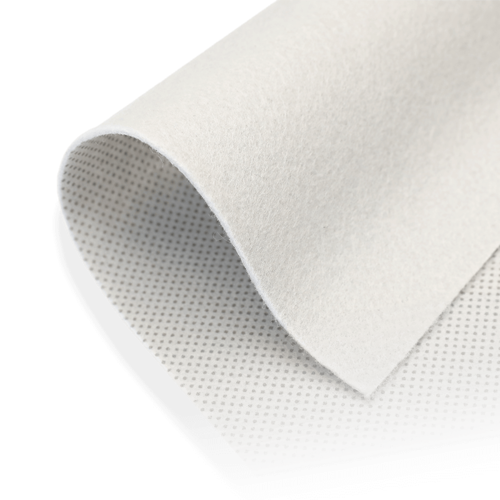

One of the key advantages of needle-punched felt non-woven fabric is its adaptability to various fiber types. Natural fibers like wool, cotton, and jute, as well as synthetic fibers such as polyester, polypropylene, and nylon, can be used to create this fabric. The choice of fiber depends on the desired properties and end-use application of the fabric.

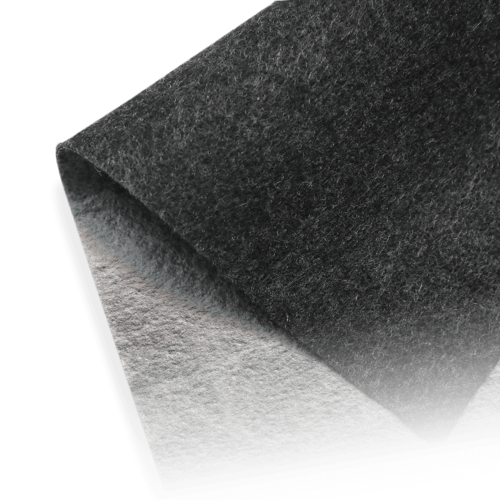

Needle-punched felt non-woven fabric is renowned for its excellent insulation properties, making it an ideal choice for thermal and acoustic insulation in buildings, vehicles, and industrial equipment. The fabric's ability to trap air between its fibers helps to regulate temperature and reduce noise levels, enhancing comfort and energy efficiency.

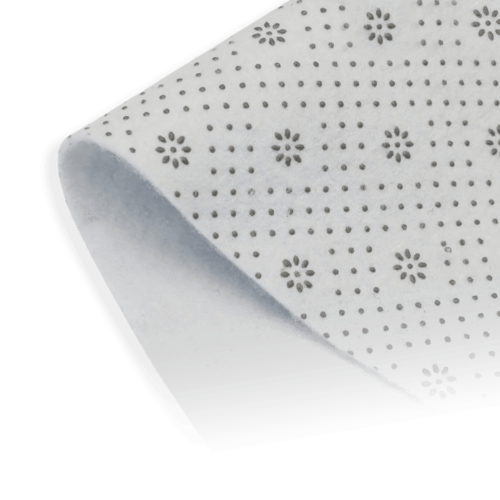

In addition to insulation, needle-punched felt non-woven fabric finds extensive use in filtration applications. The fabric's porous structure allows it to effectively capture particles, dust, and contaminants from liquids and gases, making it suitable for air and water filtration systems, as well as in the production of face masks and other personal protective equipment.

The automotive industry also heavily relies on needle-punched felt non-woven fabric for various components, such as car interior padding, sound-deadening materials, and trunk liners. The fabric's durability, lightweight nature, and moldability make it an attractive choice for vehicle manufacturers looking to enhance comfort, reduce noise, and improve overall vehicle performance.

Furthermore, needle-punched felt non-woven fabric has found its way into the world of arts and crafts. Its soft texture, easy manipulation, and ability to absorb dyes and inks make it a popular material for creating felt products, such as toys, decorations, and clothing accessories. Artists and crafters appreciate the fabric's versatility and the unique aesthetic it brings to their creations.

As sustainability becomes an increasing concern, needle-punched felt non-woven fabric offers eco-friendly solutions. Many manufacturers now use recycled fibers or biodegradable materials to produce this fabric, reducing waste and minimizing the environmental impact of production processes.

Needle-punched felt non-woven fabric has proven to be a game-changer in various industries, offering a wide range of benefits and applications. Its unique manufacturing process, versatility, and excellent properties have made it an indispensable material in sectors such as insulation, filtration, automotive, and arts and crafts. As technology advances and sustainability becomes a priority, needle-punched felt non-woven fabric is poised to play an even greater role in shaping our world.

English

English Español

Español Deutsch

Deutsch عربى

عربى