1. In the cotton blending box, put the raw fibers into the cotton blending box for loosening and mixing, because the original fiber state is lumpy, after the fiber passes through the process of the cotton blending box, the single-sided state reaches about 30%, and then It is transported to the cotton mixing box in the middle warehouse to mix the cotton layer evenly by vibration.

2. Carding machine, carding the fibers initially processed in the cotton blending box into a single fiber state. Then form a network of thin layers of fibers, which are then assembled into fiber strips and sent to the laying machine.

3. The net laying machine receives the fiber strips sent by the carding machine for net laying. The model progress of the net laying machine can be adjusted automatically through the frequency conversion four-section, so as to minimize the phenomenon that the two sides of the net are thick and the middle is thin. After the net is formed, it is sent to the needle punch machine.

4. Acupuncture machine, pre-reinforces the fiber web to form embryo cloth, and then uses triangular or other shaped cross-sections to reinforce the fiber web with barbed barbs on the edges, and puncture repeatedly.

5. Ironing the stick, using high temperature to make the fiber cotton into the ironing stick.

6. The roll forming machine receives the needle punched non-woven fabric formed by the ironing rod into rolls.

7. Measuring, weighing and packaging.

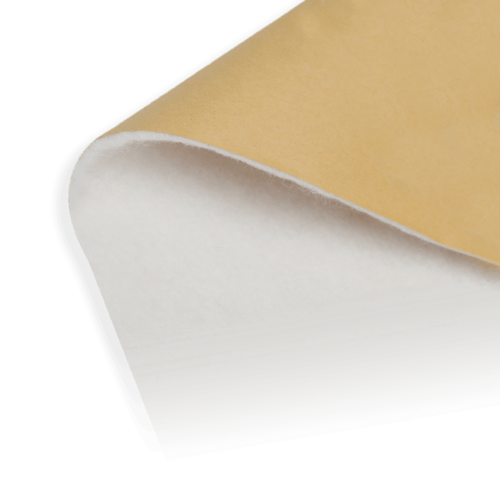

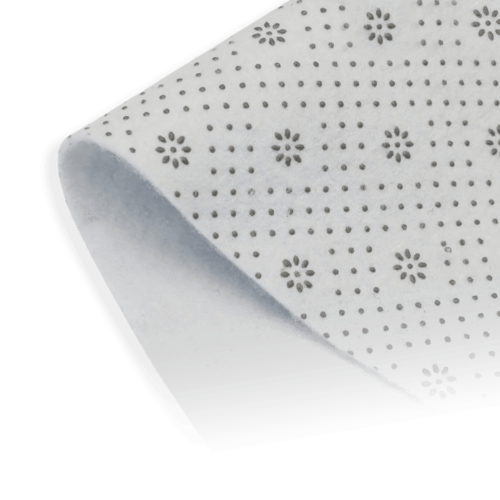

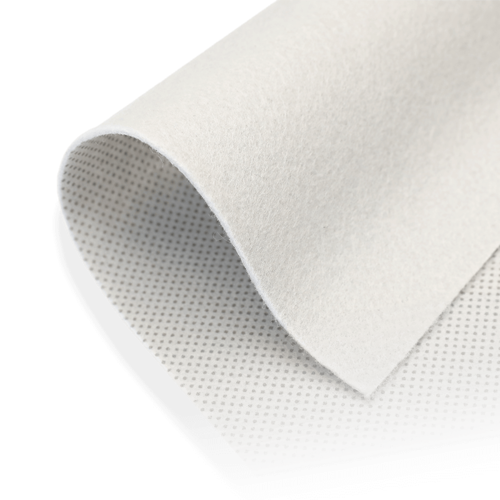

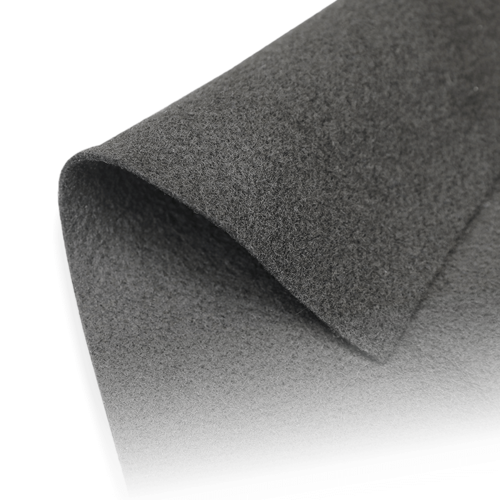

Founded in 2007, Changshu Yanrui Nonwoven Products Co., Ltd. is Custom Non Woven Fabrics Suppliers and OEM Non Woven Products Factory located in Zhitang, a land of fish and rice in the Yangtze River Delta Economic Zone, with Shanghai in the south and the Yangtze River in the north. The company has a production area of 6000 square meters and has multiple non-woven production lines. It is one of the domestic backbone enterprises specializing in the production of non-woven fabrics and other products. The annual production capacity is 5000 tons; We can produce all kinds of needle-punched non-woven fabrics and their derivatives,our company's main products include cleaning supplies, polypropylene non-woven fabrics, shoe non-woven fabrics, automotive interior fabrics, filter materials, leather base fabrics, etc. At the same time, we can also develop a variety of new non-woven products according to customers’ requirements. We sincerely hope to establish a long-term and stable partnership with all new and old friends, for mutual benefit, common development, and a better future!

Founded in 2007, Changshu Yanrui Nonwoven Products Co., Ltd. is Custom Non Woven Fabrics Suppliers and OEM Non Woven Products Factory located in Zhitang, a land of fish and rice in the Yangtze River Delta Economic Zone, with Shanghai in the south and the Yangtze River in the north. The company has a production area of 6000 square meters and has multiple non-woven production lines. It is one of the domestic backbone enterprises specializing in the production of non-woven fabrics and other products. The annual production capacity is 5000 tons; We can produce all kinds of needle-punched non-woven fabrics and their derivatives,our company's main products include cleaning supplies, polypropylene non-woven fabrics, shoe non-woven fabrics, automotive interior fabrics, filter materials, leather base fabrics, etc. At the same time, we can also develop a variety of new non-woven products according to customers’ requirements. We sincerely hope to establish a long-term and stable partnership with all new and old friends, for mutual benefit, common development, and a better future!

English

English Español

Español Deutsch

Deutsch عربى

عربى