With the continuous update and rapid development of packaging materials for sterilized items, medical non-woven fabrics have gradually entered the disinfection supply centers of various types of hospitals as the final packaging materials for sterilized items. How to control the quality of medical non-woven fabrics, you must pay attention to these ten aspects of medical non-woven fabrics

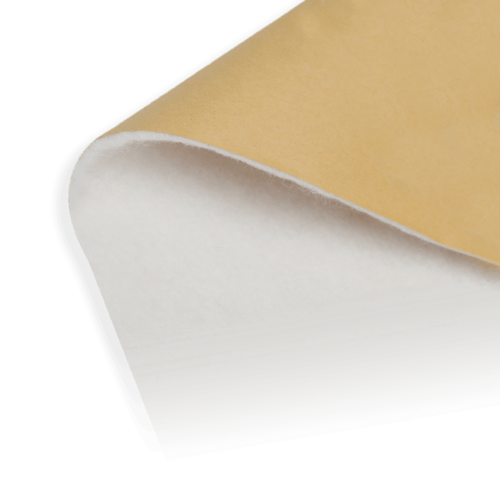

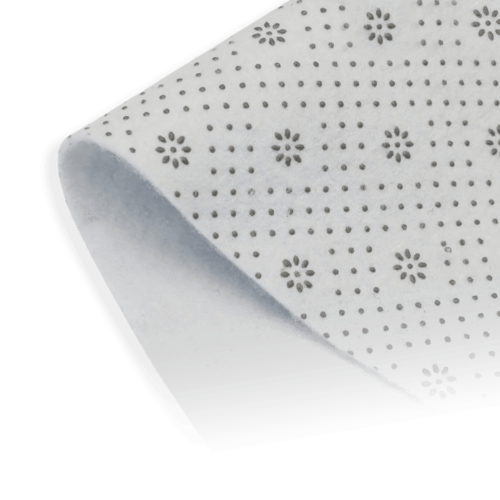

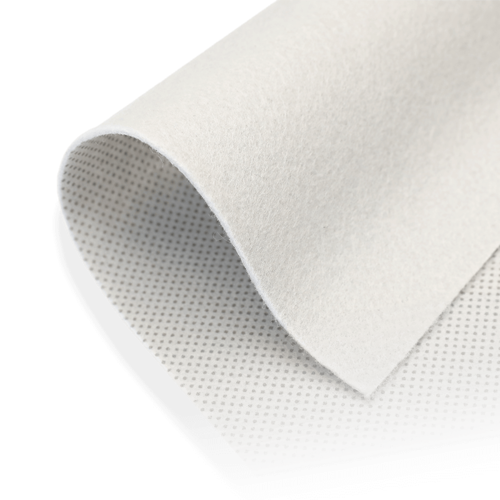

1. Medical non-woven fabrics are different from ordinary non-woven fabrics and composite non-woven fabrics. Ordinary non-woven fabrics do not have antibacterial properties; composite non-woven fabrics have good waterproof effect and poor air permeability, and are generally used for surgical gowns and surgical sheets, etc.; The non-woven fabric is made of spunbond, meltblown, spunbond (SMS) process, and has the characteristics of antibacterial, hydrophobic, breathable, and no lint. It is used for the final packaging of sterilized articles. printed non woven fabric

2. Quality standard requirements for medical non-woven fabrics: Medical non-woven fabrics used for the final packaging materials of sterilized medical devices should meet the requirements of GB/T19633 and YY/T0698.2 at the same time

3. The validity period of non-woven fabrics: the validity period of medical non-woven fabrics is generally 2 to 3 years. The validity period of products of different manufacturers is slightly different, please refer to the instructions for use. Sterile articles packaged with medical non-woven fabrics should be valid for 180 days and not be affected by the sterilization method.

4. The non-woven fabric used for the packaging of sterilized items should be 50g/m2 plus or minus 5 grams.

5. When packaging surgical instruments with medical non-woven fabrics, the closed packaging method should be used, and two layers of non-woven fabrics should be packaged in two times. Repeated folding can form a long curved path to prevent microorganisms from "easily" entering the sterilization package. 2 layers of non-woven fabrics cannot be used for 1 packaging non woven shoe lining fabric

6. After high-temperature sterilization of medical non-woven fabrics, the internal results will change, which will affect the penetration and antibacterial properties of the sterilization medium. Therefore, medical non-woven fabrics should not be repeatedly sterilized for use.

7. Due to the hydrophobic properties of non-woven fabrics, excessive and heavy metal instruments are sterilized at high temperature, and condensed water is formed during the cooling process, which is prone to wet packs. Therefore, pad water-absorbing material in the large instrument bag, appropriately reduce the loading capacity of the sterilizer, leave a gap between the sterilization bags, and appropriately prolong the drying time, and try to avoid the generation of wet bags.

8. Special non-woven fabrics should be used for low-temperature plasma of hydrogen peroxide, and medical non-woven fabrics containing plant fibers cannot be used, because plant fibers will absorb hydrogen peroxide.

9. Although medical non-woven fabrics are not medical devices, they are related to the sterilization quality of medical devices. The quality of medical non-woven fabrics as packaging materials and the packaging method are very important to ensure the sterility level.

10. Refer to the inspection report and product batch inspection report provided by the manufacturer, and check the physical and chemical properties of the medical non-woven fabric to ensure the quality of the product used.

English

English Español

Español Deutsch

Deutsch عربى

عربى