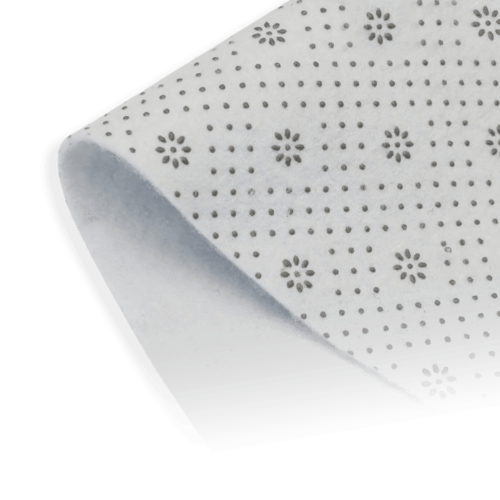

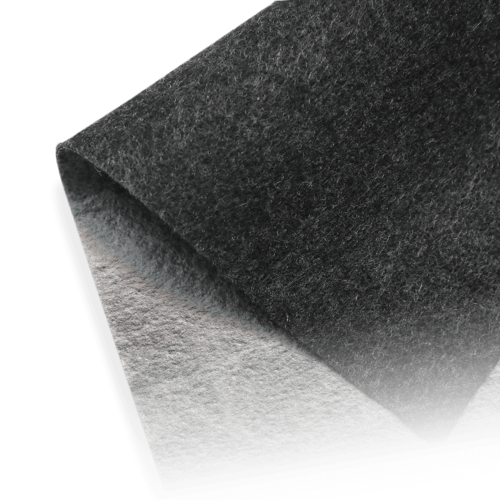

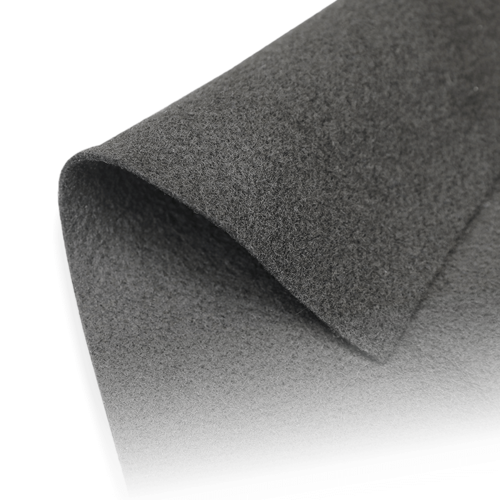

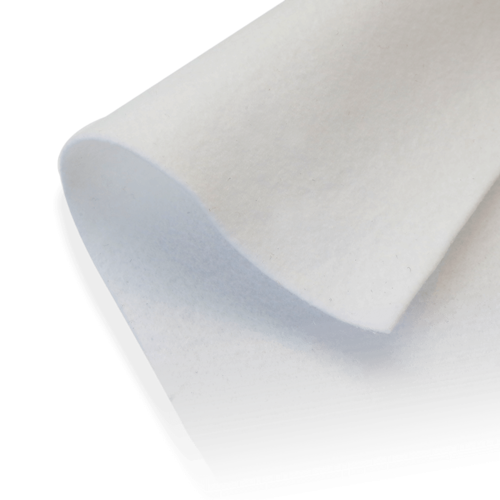

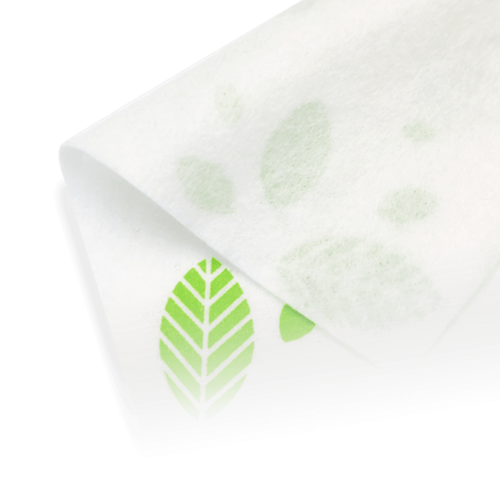

In the context of the current global epidemic, the demand for personal protective equipment (PPE) is growing day by day. As an important material in the production of PPE, polypropylene (PP) non-woven fabric plays a vital role. It not only has good protective properties, but also has breathability and comfort, providing strong support for the quality and comfort of PPE.

PP non-woven fabric plays an important role in mask manufacturing. Due to its fine fiber structure and high strength properties, PP non-woven fabrics are widely used in the filter layer and outer layer of medical masks. It effectively blocks particles and liquid splashes, protecting the respiratory tract from external pollutants. Compared with traditional textiles, PP non-woven fabrics are lighter and more comfortable, allowing mask wearers to wear them for long periods of time without feeling discomfort.

In addition, PP non-woven fabrics are also widely used in the manufacture of protective clothing. Protective clothing needs to be waterproof, dustproof, anti-static and other functions, and PP non-woven fabrics have these properties. It can achieve waterproof and anti-static effects through special processing technology, and has good breathability, allowing the wearer to remain comfortable while working for a long time.

In addition, PP non-woven fabrics are also used to produce PPE products such as gloves, hats, and shoe covers. Its excellent physical and chemical properties enable PPE products to provide reliable protection during use while ensuring user comfort.

As an important material in the production of PPE, PP non-woven fabric provides us with important protection and comfort guarantee. Under the current epidemic, its role has become even more prominent, protecting our safety and health.

English

English Español

Español Deutsch

Deutsch عربى

عربى