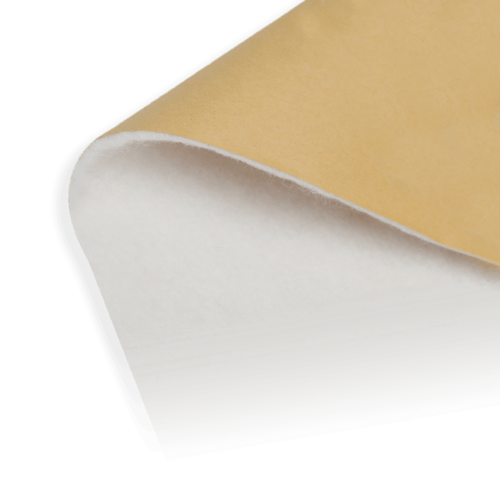

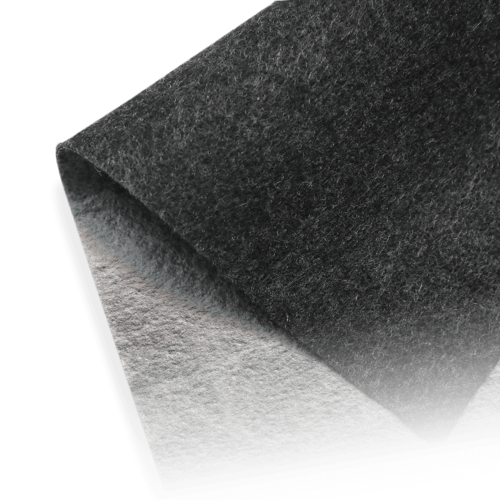

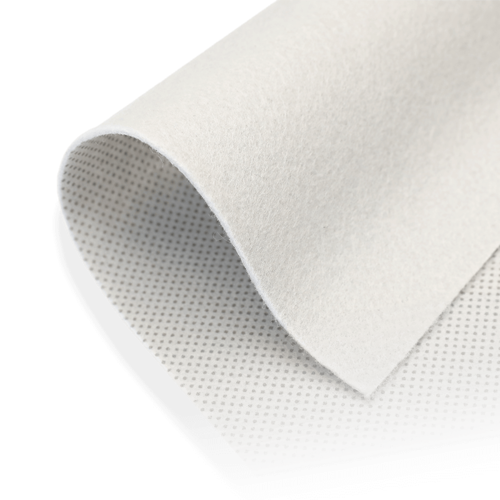

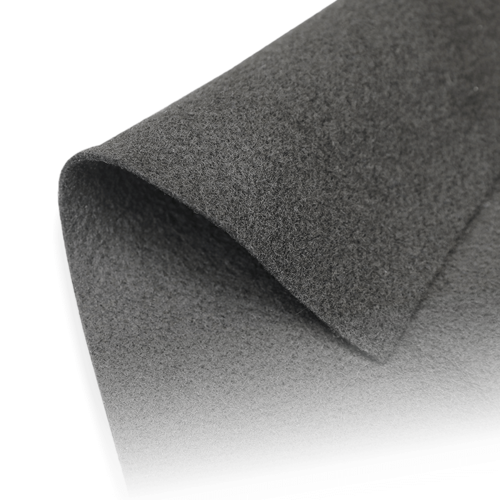

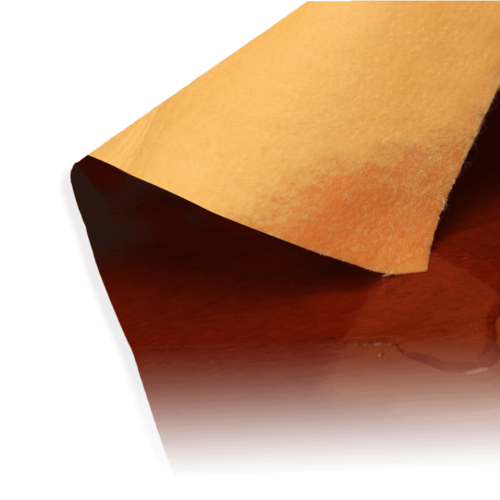

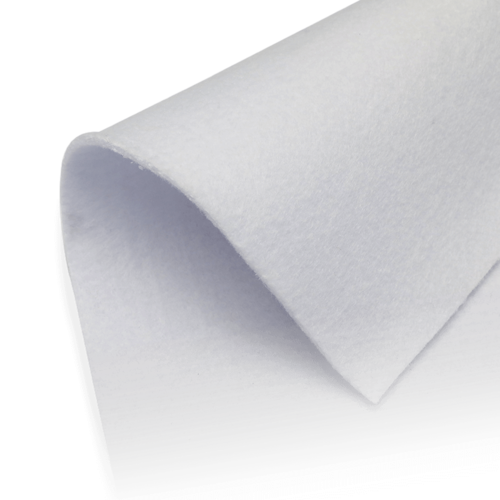

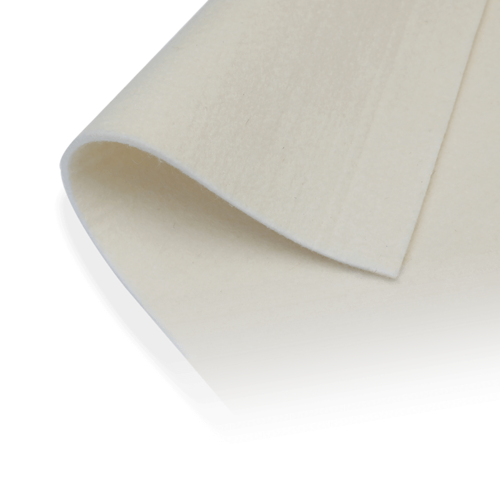

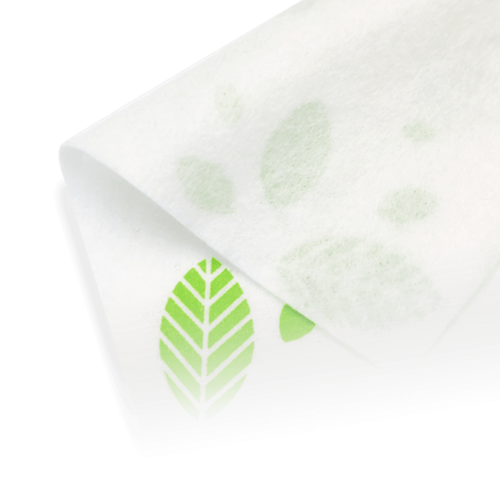

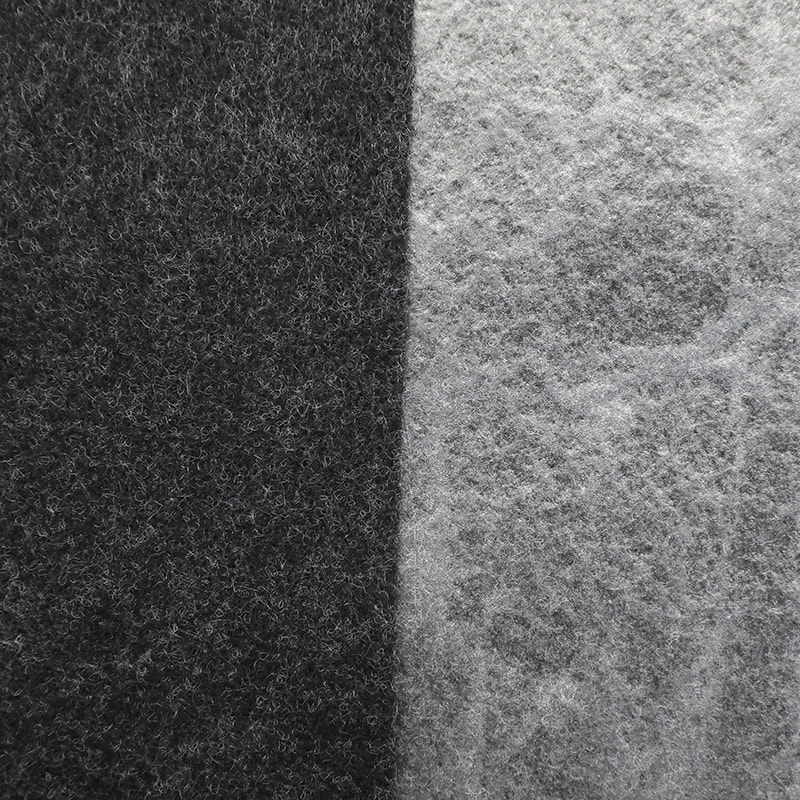

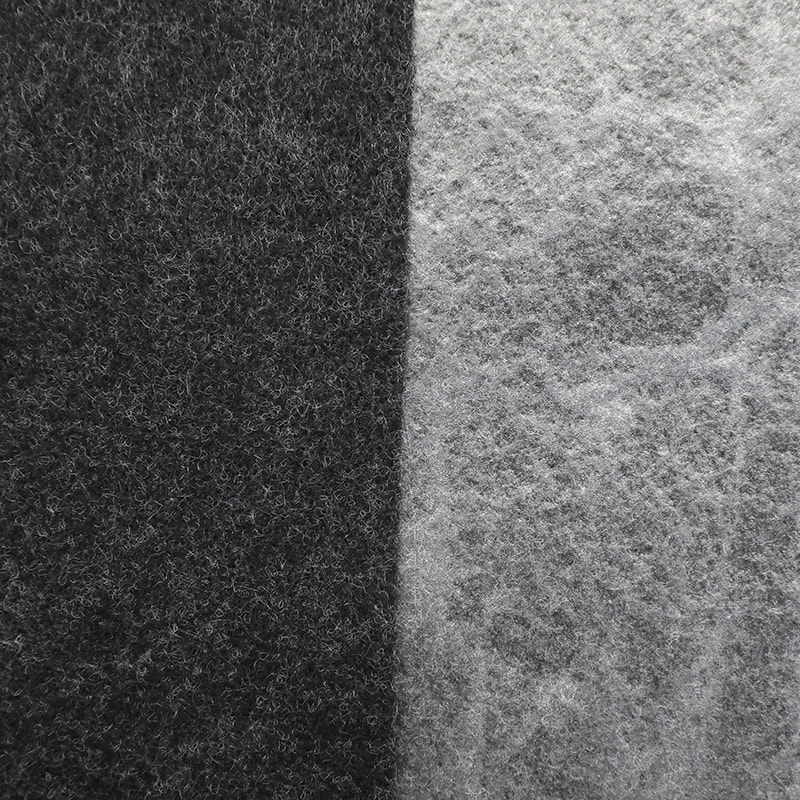

Laminated non-woven fabric is a type of material that consists of two or more layers of non-woven fabric that have been bonded together using a lamination process. Some of the properties of laminated non-woven fabric include:

Durability: Laminated non-woven fabric is known for its durability and strength, which makes it ideal for use in various applications.

Water resistance: The lamination process used to bond the layers of fabric together can make the resulting material resistant to water and other liquids.

Breathability: Despite its water-resistant properties, laminated non-woven fabric can still be breathable, depending on the specific type of fabric and lamination process used.

Flexibility: Laminated non-woven fabric is flexible and can be easily molded and shaped to fit various applications.

Resistance to tearing: Due to its multi-layered structure, laminated non-woven fabric is resistant to tearing and can withstand some degree of wear and tear.

Cost-effective: Laminated non-woven fabric can be produced at a relatively low cost, which makes it an attractive option for various industries and applications.

Overall, laminated non-woven fabric is a versatile material that can be used in a wide range of applications due to its unique properties.

English

English Español

Español Deutsch

Deutsch عربى

عربى