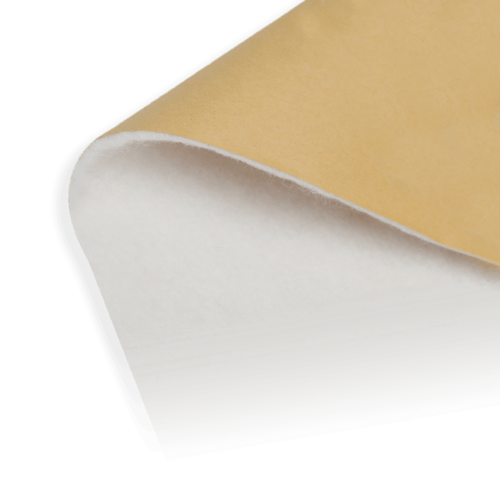

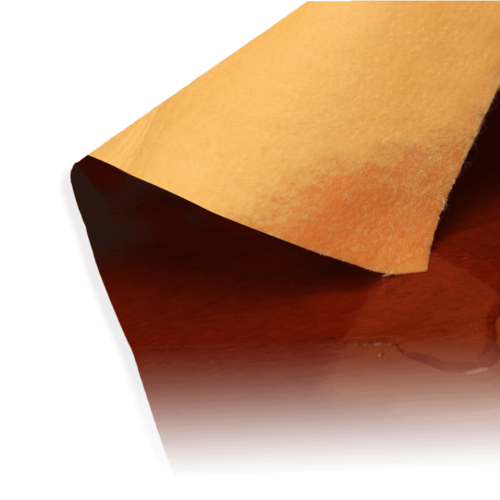

Advanced composite materials refer to composite materials with complex geometric shapes or specific design structures, which can be integrated into prefabricated bodies through technologies such as 3D weaving, 3D weaving, 3D knitting, and 3D non-woven. Three dimensional weaving is formed by interweaving fibers in different spatial positions to create a cohesive structure. The resulting structural material has good resistance to delamination and overall integrity, and is commonly used in structural materials such as engine mounts, antenna covers, and radar covers. 3D weaving technology can weave various shaped structures at once, commonly used in antenna covers, fairings, radar covers, missile shells, etc. Advanced composite materials with irregular structures are widely used in various components of rocket missiles. The nozzle extension section of the liquid rocket engine is made of carbon fiber composite material, and the forming methods of its prefabricated body include three-dimensional weaving and three-dimensional needle punching. The composite materials prepared by three-dimensional weaving technology have good overall integrity, but due to limitations in machine equipment, the sample size is usually small. The French company Snecma has used three-dimensional needle punching technology to achieve efficient and low-cost molding of the extended section of rocket engine nozzles. When a missile is running at high speed, its shell will experience severe friction with the atmosphere, resulting in a sharp increase in temperature. Therefore, a non-woven glass fiber felt or carbon fiber felt protective layer should be used on the missile shell to avoid damage from high temperatures. In addition, missile engines can also use glass fiber reinforced shells, organic fiber reinforced shells, and carbon fiber reinforced shells. In the future, textile materials for aerospace will further develop towards lightweight, large-scale, intelligent, multifunctional, and environmentally friendly and energy-saving directions. In terms of lightweighting, it is necessary to improve the specific strength of high-performance fiber materials. Through textile structure design and optimization, structural materials can withstand larger effective loads, increase carrying capacity, and achieve comprehensive localization of materials. Meanwhile, the continuous development of fiber composite material technology and nanomaterials is bound to bring new breakthroughs to the lightweighting of aerospace equipment. In terms of large-scale development, with the deepening of communication, space stations, deep space exploration and other fields, ultra large spacecraft will become a major strategic space equipment for future space resource utilization, exploration of cosmic mysteries, and long-term in orbit residence. In terms of multifunctionality, due to the complex aerospace environment, materials are required to meet multiple performance indicators. Therefore, new materials with multiple functions can enhance their adaptability to extreme environments. In terms of environmental protection and energy conservation, aerospace grade materials usually have high costs and most of them are discarded. If recycling technology is successfully implemented, the cost of entering space can be reduced. It will enable the reuse of most components, making space exploration more economical and efficient.

English

English Español

Español Deutsch

Deutsch عربى

عربى