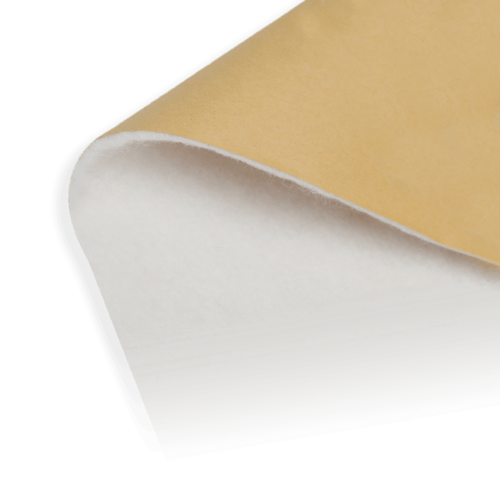

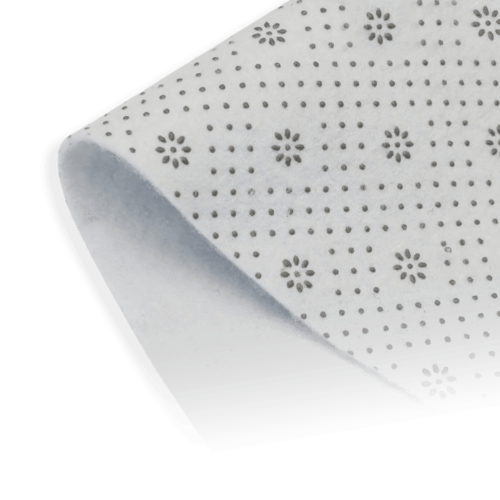

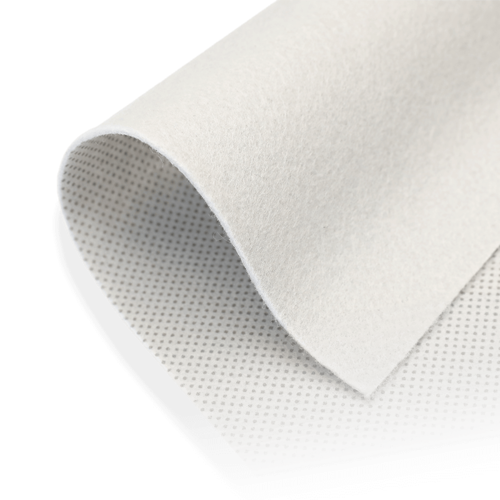

The exact name of non-woven fabric is non-woven fabric, or non-woven fabric. It is a kind of fabric that does not need to be spun and weaving. It breaks through the traditional textile and has short process flow, fast production speed, high output and low cost. And many other performance characteristics.

(1) Physical properties: PP non-woven fabric is a non-toxic, odorless, milky white highly crystalline polymer. It is currently one of the lightest varieties of all plastics. It is particularly stable to water, and its water absorption rate in water is only 0.01 for 14 hours. %. The molecular weight is between 80,000 and 150,000, and the moldability is good. However, due to the large shrinkage rate, the original wall products are easy to dent, the surface of the products has good gloss and is easy to color.

(2) Mechanical properties: PP non-woven fabric has high crystallinity and regular structure, so it has excellent mechanical properties. Its strength, hardness and elasticity are higher than high-density PE (HDPE). The outstanding feature is the resistance to bending fatigue (7×10^7) times of opening and closing without damage. The coefficient of dry friction is similar to nylon, but it is not as good as nylon under oil lubrication.

(3) Thermal performance: PP non-woven fabric has good heat resistance, melting point is 164~170℃, and products can be sterilized at temperatures above 100℃. No deformation at 150°C under no external force. The embrittlement temperature is -35℃, embrittlement will occur below -35℃, and the heat resistance is not as good as PE.

(4) Chemical stability: PP non-woven fabric has good chemical stability. In addition to being corroded by acid, it is relatively stable to other chemical reagents, but low molecular weight aliphatic hydrocarbons and aromatic hydrocarbons can make PP non-woven The cloth softens and swells, and its chemical stability improves with the increase of crystallinity. Therefore, PP non-woven fabric is suitable for making Russian-Chinese chemical pipelines and fittings, and has good anti-corrosion effects.

(5) Electrical properties: non-woven fabrics have excellent high-frequency insulation properties. Because it hardly absorbs water, the insulation properties are not affected by humidity, have a higher dielectric coefficient, and can be used to make heat-resistant fabrics as the temperature rises. The electrical insulation products have a high breakdown voltage and are suitable for electrical accessories. Good resistance to voltage and arc, but high static electricity, easy to aging in contact with copper.

(6) Weather resistance: Non-woven fabrics are very sensitive to ultraviolet rays. Adding zinc oxide thiopropionic acid dilaurate, carbon black-like milky white fillers, etc. can improve its aging resistance.

(1) Physical properties: PP non-woven fabric is a non-toxic, odorless, milky white highly crystalline polymer. It is currently one of the lightest varieties of all plastics. It is particularly stable to water, and its water absorption rate in water is only 0.01 for 14 hours. %. The molecular weight is between 80,000 and 150,000, and the moldability is good. However, due to the large shrinkage rate, the original wall products are easy to dent, the surface of the products has good gloss and is easy to color.

(2) Mechanical properties: PP non-woven fabric has high crystallinity and regular structure, so it has excellent mechanical properties. Its strength, hardness and elasticity are higher than high-density PE (HDPE). The outstanding feature is the resistance to bending fatigue (7×10^7) times of opening and closing without damage. The coefficient of dry friction is similar to nylon, but it is not as good as nylon under oil lubrication.

(3) Thermal performance: PP non-woven fabric has good heat resistance, melting point is 164~170℃, and products can be sterilized at temperatures above 100℃. No deformation at 150°C under no external force. The embrittlement temperature is -35℃, embrittlement will occur below -35℃, and the heat resistance is not as good as PE.

(4) Chemical stability: PP non-woven fabric has good chemical stability. In addition to being corroded by acid, it is relatively stable to other chemical reagents, but low molecular weight aliphatic hydrocarbons and aromatic hydrocarbons can make PP non-woven The cloth softens and swells, and its chemical stability improves with the increase of crystallinity. Therefore, PP non-woven fabric is suitable for making Russian-Chinese chemical pipelines and fittings, and has good anti-corrosion effects.

(5) Electrical properties: non-woven fabrics have excellent high-frequency insulation properties. Because it hardly absorbs water, the insulation properties are not affected by humidity, have a higher dielectric coefficient, and can be used to make heat-resistant fabrics as the temperature rises. The electrical insulation products have a high breakdown voltage and are suitable for electrical accessories. Good resistance to voltage and arc, but high static electricity, easy to aging in contact with copper.

(6) Weather resistance: Non-woven fabrics are very sensitive to ultraviolet rays. Adding zinc oxide thiopropionic acid dilaurate, carbon black-like milky white fillers, etc. can improve its aging resistance.

As the demand for non-woven fabrics continues to grow, the non-woven fabric industry still has great growth potential in the future.

English

English Español

Español Deutsch

Deutsch عربى

عربى