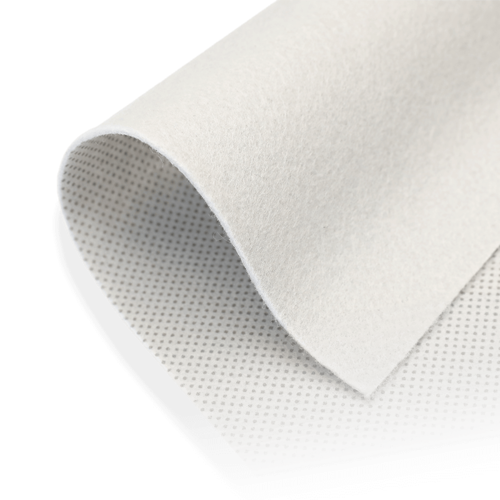

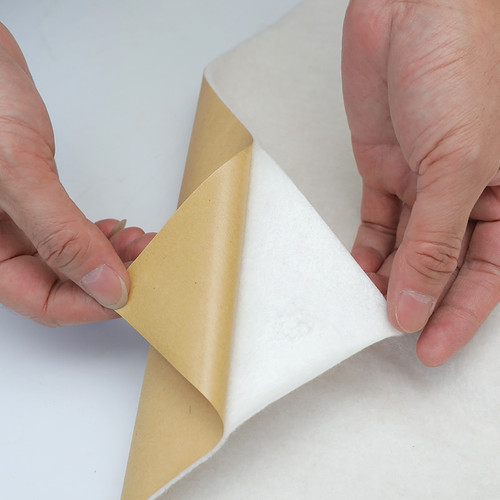

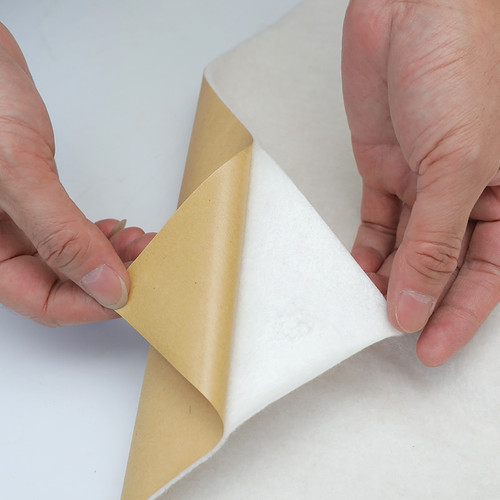

Adhesive non-woven fabric is a common bonding method that offers many advantages in a variety of applications. This article will give you a detailed introduction to the unique advantages of bonded non-woven fabrics compared to other bonding methods, allowing you to understand its charm in certain applications.

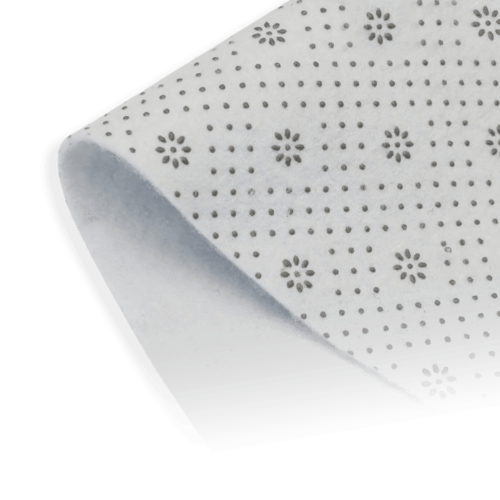

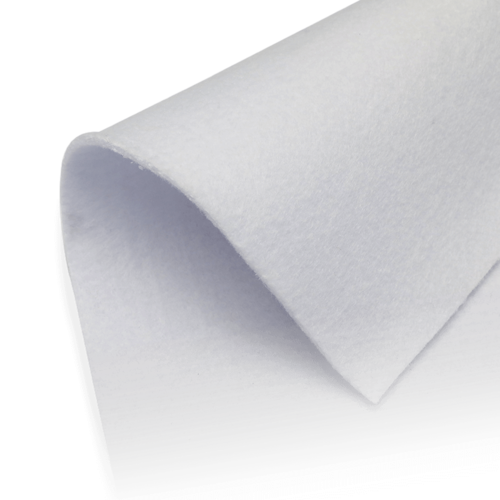

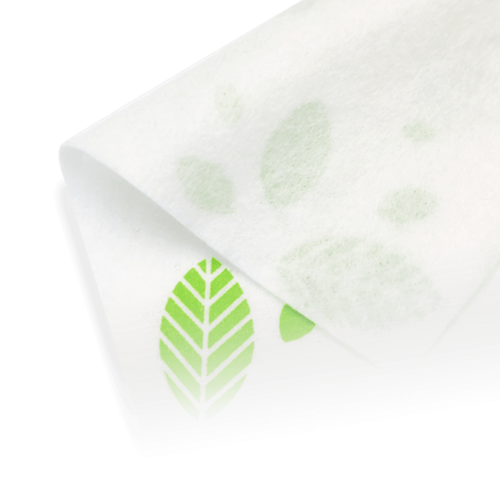

Good breathability and comfort

The unique structure of adhesive non woven fabric makes it highly breathable, meaning air and water vapor can freely penetrate the material. In contrast, other bonding methods may create a tight, closed structure that results in less breathability. In some applications, such as medical supplies, sanitary napkins, masks, etc., breathability is crucial. The breathable properties of adhesive non-woven fabric make the product more comfortable and reduce the feeling of moisture and airtightness.

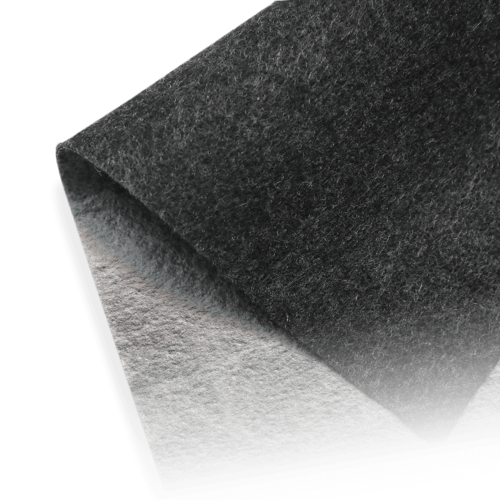

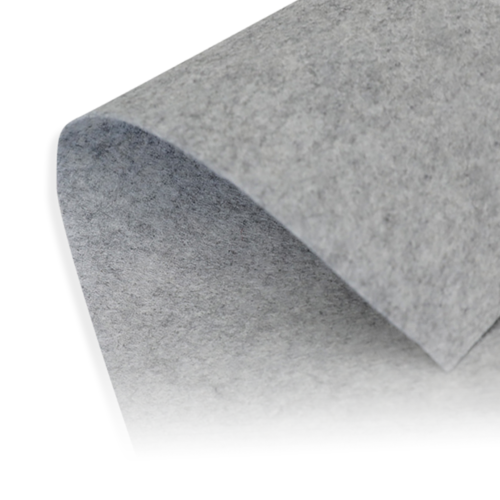

Excellent softness and elasticity

Adhesive non-woven fabric is usually made of fibers that are bonded by hot melt or chemical bonding, which gives it good softness and elasticity. Adhesive non-woven fabric conforms to a variety of shapes and curves better than other bonding methods, making it excellent in some applications that require conformal performance. For example, in products such as dressings, elastic bands, and elastic clothing in the medical field, the softness and elasticity of adhesive non-woven fabric can provide better comfort and fit.

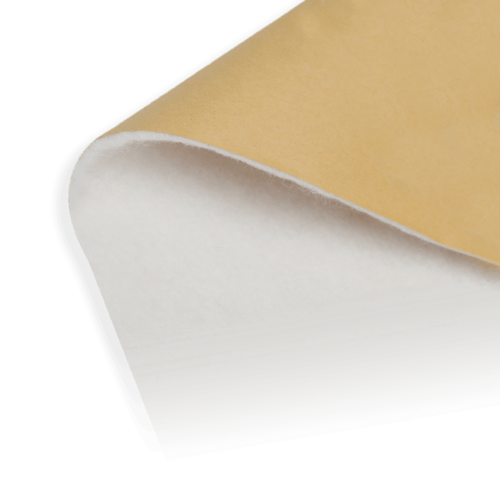

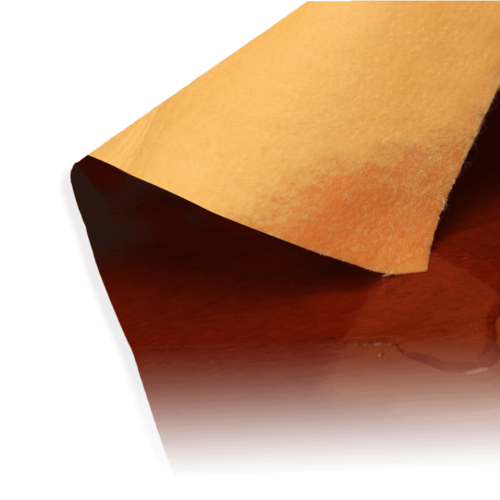

Good water resistance and abrasion resistance

After adhesive treatment, adhesive non-woven fabric usually has better water resistance and wear resistance. This makes it advantageous in some applications where waterproofing and durability are required. For example, in the fields of outdoor products, car interiors, household products, etc., the water resistance and wear resistance of adhesive non woven fabric can meet the needs of use in various complex environments.

Adhesive non-woven fabric has unique advantages over other bonding methods in certain applications. Its good breathability and comfort make the product more suitable for long-term wear, its excellent softness and elasticity provide better fit, and its good water resistance and wear resistance make the product more durable. Therefore, when choosing a bonding method, bonded nonwovens may be an ideal choice given the needs of the specific application.

English

English Español

Español Deutsch

Deutsch عربى

عربى