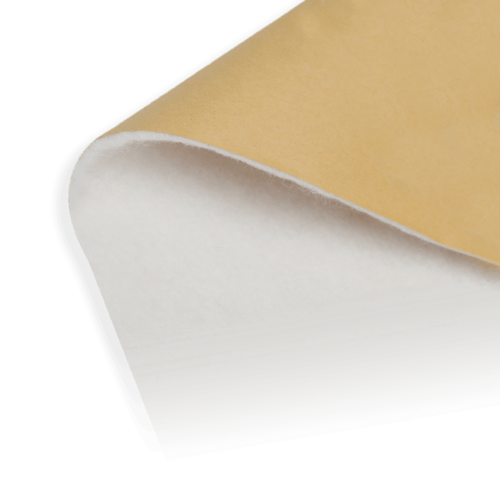

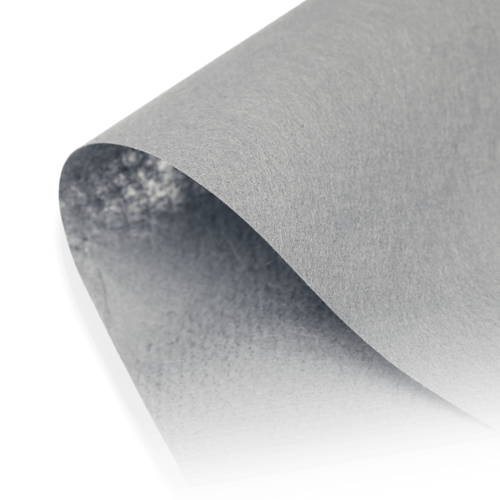

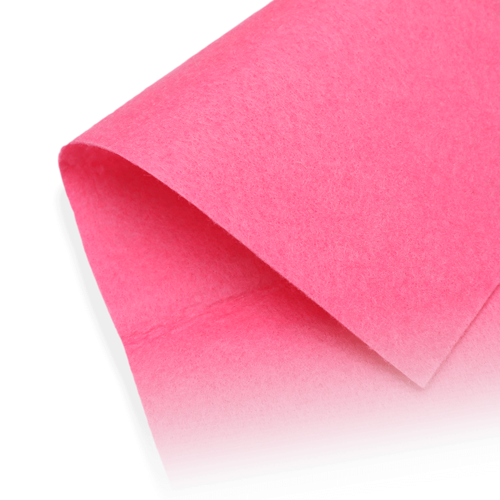

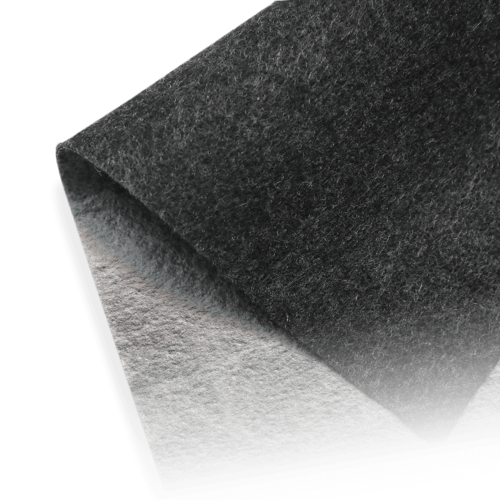

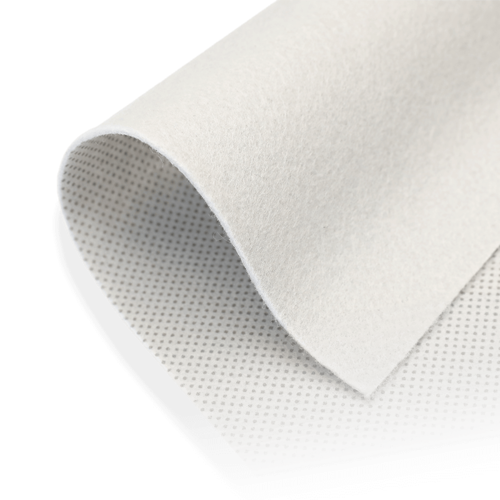

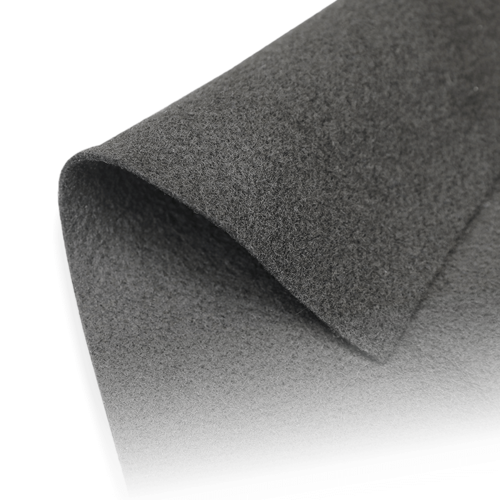

In our daily life, we often come into contact with a variety of materials, including non-woven fabrics. As a common material, non-woven fabrics have many advantages, such as wear resistance and good breathability. But how does it compare to other materials in terms of absorbency and wicking properties? Today, let’s learn more about it.

Water absorption is one of the important indicators to measure the ability of a material to absorb moisture. Compared with other materials, PP non-woven fabrics have poor water absorption properties. This is because the fiber structure of PP non-woven fabric is relatively tight, making it difficult for moisture to penetrate. In contrast, natural fiber materials such as cotton have better water absorption properties due to the larger gaps between fibers. Therefore, where high water absorbency is required, other materials may be more appropriate.

Wicking performance refers to the material's ability to quickly conduct moisture to the interior of the material after absorbing water, and maintain the water absorption performance for a long time. Compared with other materials, PP non-woven fabric also has poor wicking performance. Due to its tight fiber structure, it is difficult for moisture to conduct quickly inside the material, resulting in slower water absorption. Some materials specifically designed for water absorption, such as bamboo fiber, have better wicking properties due to their unique fiber structure.

Although PP non-woven fabric is relatively poor in water absorption and wicking performance, it still has its unique advantages. Due to its tight fiber structure, PP non-woven fabric has good waterproof properties and can be used to make waterproof materials. In addition, PP non-woven fabric also has high wear resistance and breathability, and is suitable for some special fields.

Compared with other materials, PP non-woven fabric is relatively poor in water absorption and wicking properties. However, PP non-woven fabric still has other advantages, such as waterproof performance, abrasion resistance and breathability. When selecting materials, we need to choose according to specific needs and usage scenarios to achieve the best results.

English

English Español

Español Deutsch

Deutsch عربى

عربى