The ability of absorbent non-woven fabric to retain absorbed liquid is a crucial property that ensures the liquid remains locked within the fabric and does not leak or seep out. This property is often referred to as "liquid retention" or "fluid retention," and it is essential in various applications where maintaining a dry or controlled environment is important, such as in hygiene products, wound care, and spill cleanup materials.

Here are some key factors that contribute to the ability of absorbent non-woven fabric to retain absorbed liquid:

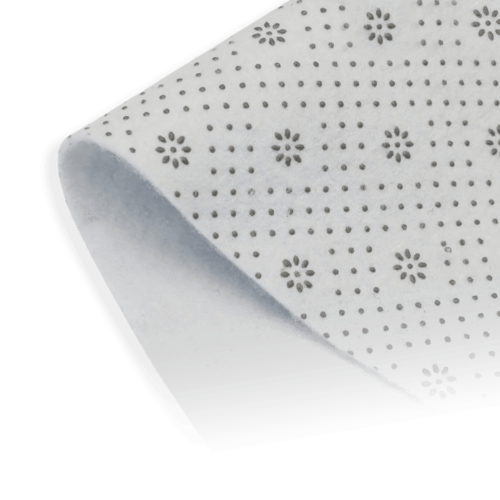

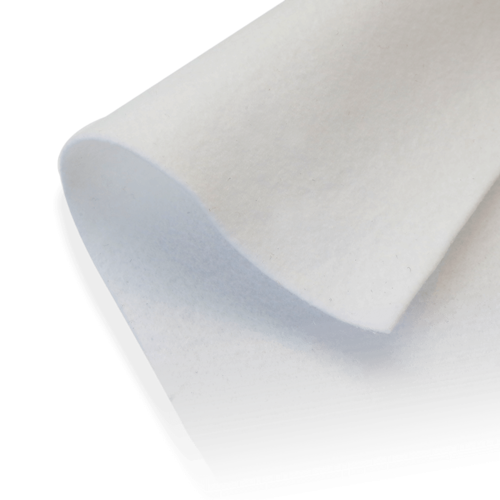

Fiber Structure: The structure of the non-woven fabric's fibers can play a significant role in liquid retention. Fibers may be engineered to create capillary action, which helps hold liquid within the fabric.

Binding Agents: Some absorbent non-woven fabrics may include binding agents or chemicals that improve the adhesion of liquid molecules to the fabric's surface, enhancing retention.

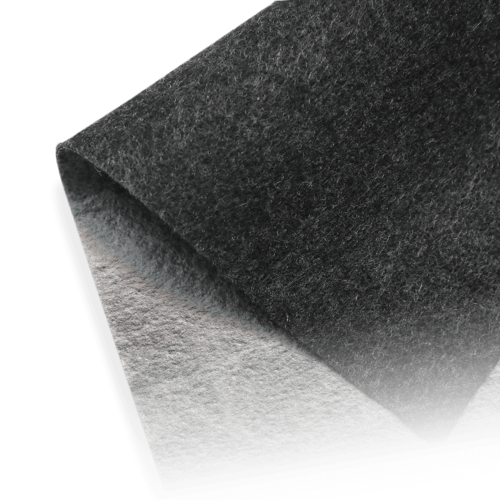

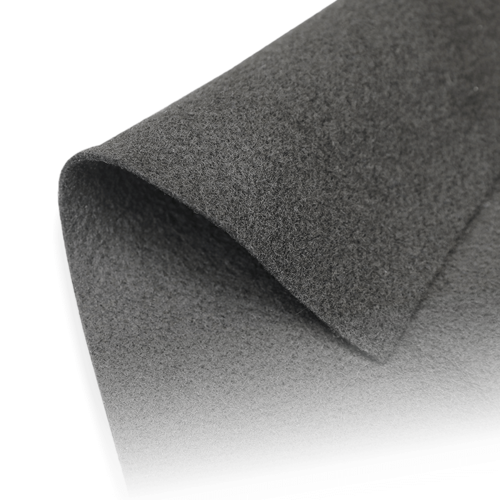

Fabric Density: Higher fabric density can contribute to better liquid retention, as there is less open space for liquid to escape from the fabric.

Absorbent Core Design: In products like diapers and sanitary pads, absorbent cores are designed with layers or structures that optimize liquid retention. Superabsorbent polymers (SAPs) are often used in these cores to absorb and retain liquids effectively.

Hydrophobic Barriers: In certain applications like medical dressings or automotive oil spill cleanup materials, non-woven fabrics may incorporate hydrophobic (water-repellent) barriers to prevent liquid from escaping once absorbed.

Thickness: Thicker non-woven fabrics can generally hold more liquid and may provide better retention. However, the thickness should be balanced with other factors like comfort and practicality for specific applications.

Testing and Quality Control: Manufacturers often conduct tests to ensure that their absorbent non-woven fabrics meet specific retention requirements. This can involve evaluating how much liquid the fabric can hold without leakage under various conditions.

Application-Specific Design: The design of absorbent non-woven fabrics can be tailored to meet the retention needs of specific applications. For example, medical dressings need to retain wound exudate without leaking, while automotive spill cleanup materials need to hold oils and fluids securely.

English

English Español

Español Deutsch

Deutsch عربى

عربى