The absorbency capability of absorbent non-woven fabric can vary significantly depending on several factors, including the specific type of fabric, its composition, and how it has been engineered. However, absorbent non-woven fabrics are designed to efficiently absorb and retain liquids, and their absorbency is generally measured in terms of their weight or capacity to hold fluids.

Here are some general guidelines for absorbency capability:

Absorption Capacity: Absorbent non-woven fabrics can typically absorb several times their weight in liquids. For example, some high-quality disposable diapers can absorb 15 to 20 times their weight in urine.

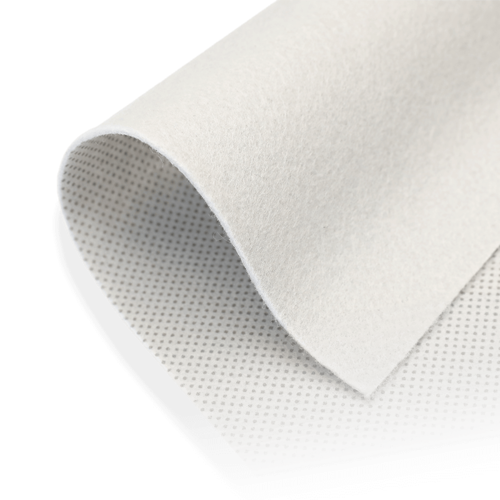

Wicking: These fabrics are often engineered to wick liquids quickly, spreading them across the fabric's surface for more effective absorption. This helps prevent localized saturation and leakage.

Retention: Absorbent non-woven fabrics are designed to retain absorbed liquids, preventing them from leaking or seeping back out. The retention capacity depends on the fabric's structure and the type of liquid it's designed to absorb.

Thickness and Density: Thicker and denser non-woven fabrics can generally hold more liquid than thinner or less dense ones. The design can be customized to meet specific absorbency requirements.

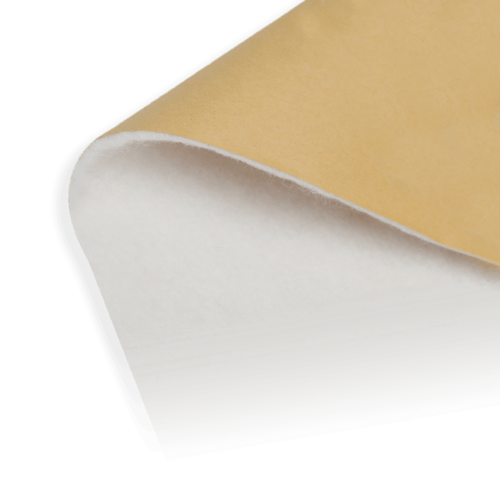

Composition: The choice of materials and fibers used in the non-woven fabric can impact its absorbency. Synthetic materials like polypropylene or polyester are often used for their hydrophobic (water-repelling) properties, while natural fibers like cotton can be used for their absorbency.

Special Treatments: Some absorbent non-woven fabrics are treated with chemicals or additives to enhance their absorbency, wicking, or retention properties. These treatments can further increase their absorbency capability.

Application-Specific Design: The absorbency of non-woven fabrics can be tailored to meet the requirements of specific applications. For example, wound dressings may have different absorbency needs compared to automotive oil spill cleanup materials.

When selecting an absorbent non-woven fabric for a particular application, it's essential to consider the specific absorbency requirements of that application and consult with manufacturers or suppliers to ensure the chosen material meets those needs effectively. Testing and standard methods, such as the AATCC (American Association of Textile Chemists and Colorists) Test Method 79, can be used to quantify and compare the absorbency of different non-woven fabrics.

English

English Español

Español Deutsch

Deutsch عربى

عربى